Considerations for Choosing of 4 Axis CNC Machining

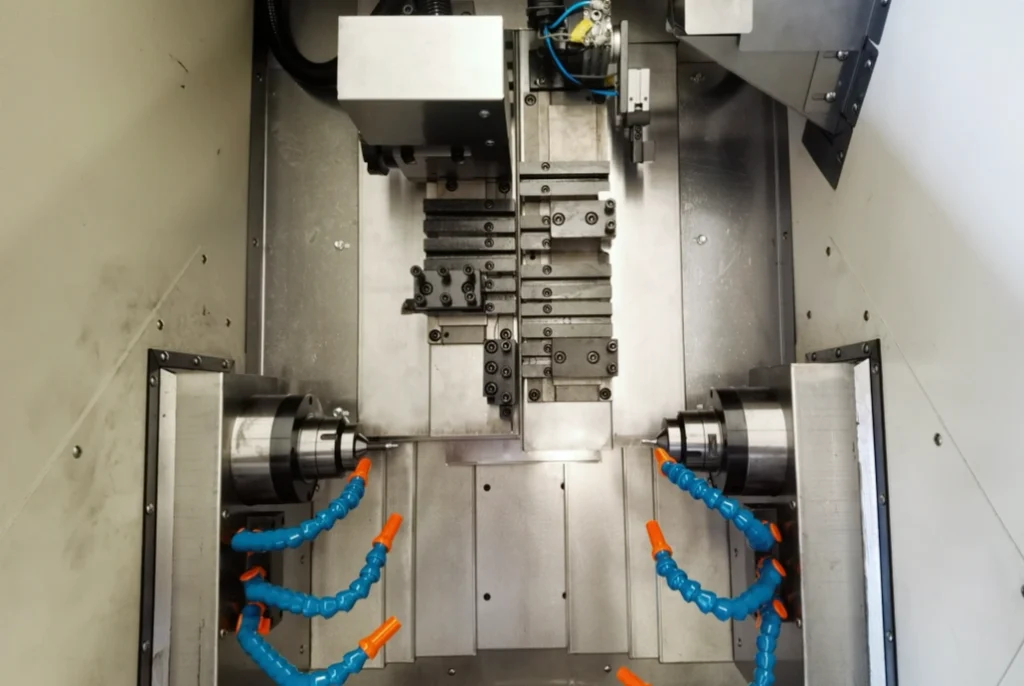

When selecting 4-axis milling, several factors must be considered to ensure it’s the best choice for the project.

Cost: 4-axis milling offers a balance between cost and capability—cheaper than 5-axis but pricier than 3-axis.

Material Properties: Material type affects tooling, machining parameters, and overall suitability for 4-axis milling.

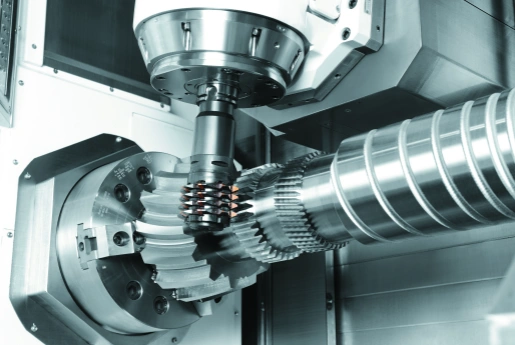

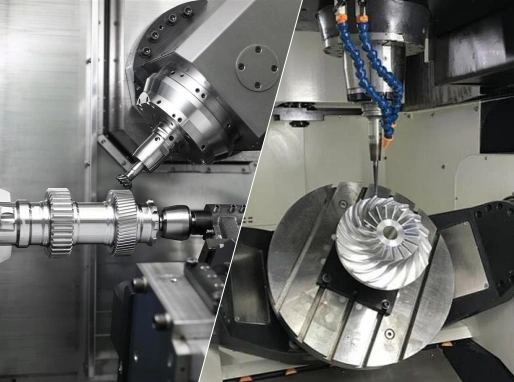

Part Complexity: Ideal for parts with features on multiple sides, reducing setups and improving efficiency.

Required Tolerances: 4-axis can achieve high accuracy, but ultra-tight tolerances may need 5-axis capabilities.