Rapid prototyping services in Bas-Rhin

Our rapid prototyping service, in Bas-Rhin , makes quality components for your needs.

Our rapid prototyping service, in Bas-Rhin , makes quality components for your needs.

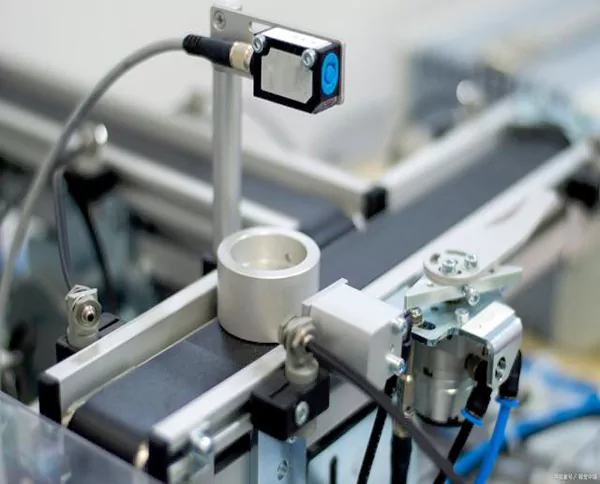

We are proud to offer top-tier Rapid Prototyping Services in Bas-Rhin, catering to diverse industries and bringing your innovative ideas to life with speed and precision. Utilizing the latest CAD software and advanced 3D printing technology, we transform your designs into tangible prototypes swiftly, enabling faster design validation and functional testing. Whether you’re in aerospace, automotive, healthcare, or any other sector, our expert team is dedicated to delivering high-quality prototypes that help you stay ahead in the competitive market. Partner with us to accelerate your product development process efficiently and effectively.

optimal production method. CNC machining allows for the creation of precise prototypes with detailed accuracy and ensures completion within a short lead time.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 7500×3400×1200mm / 295×133.8×47 in. | 200×500 mm / 7.9×19.7 in. |

| Minimum Part Size | 3.5×3.5 mm / 0.13×0.13 in. | 2×2 mm 0.079×0.079 in. |

| Standard Tolerances | +/- 0.01 mm +/- 0.0004 in. | +/- 0.01 mm +/- 0.0004 in. |

| Dimension | Metals: ISO 2768-m Plastics: ISO 2768-c | |

| Standards | Description |

| Thickness wall | 1.0 mm |

| Layer height | 50 – 300 μm |

| Max. build size | 250 * 250 * 250 mm (SLA), 420 * 500 * 420 mm (SLS) |

| Tolerance | ± 0.5% |

| Dimension | Tolerance |

| Edge to edge, single surface / Edge to hole, single surface / Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface / Over formed part, multiple surface | +/- 0.030 inch |

| Angle | +/- 1° |

| Standard | Description |

| Maximum build size | +/- 0.025 mm (+/- 0.001 inch) |

| Standard lead time | Up to 20 parts in 15 days or less |

| Accuracy | ±0.05 mm |

| Layer thickness | 1.5mm – 2.5mm |

Upload your design to our quoting platform to receive instant, automated quotes along with a complimentary design analysis for your prototypes and production parts.

A design for manufacturability analysis will be completed for you within a few hours.

Once you place your order, we initiate the manufacturing process. Additionally, our digital platform provides real-time updates on the production stage.

After passing quality inspections, the parts are carefully packed for delivery. You can rest assured with our 30-day quality guarantee.

Enables manufacturers to create physical models of a product design to validate its form, fit, and function.

This allows for quick iterations and modifications of a product design based on feedback and testing.

Allows for the creation of prototypes that can be tested under real-world conditions to evaluate performance, and functionality.

Facilitates the creation of custom and complex parts that might be difficult or impossible to produce using traditional methods.

Allows for the creation of prototypes of tools, jigs, and fixtures used in the manufacturing process to produce and assemble products.

Produces prototypes that can be used for market testing, gathering customer feedback, and pre-production marketing.

Rapid prototyping services in none, Bas-Rhin, play a crucial role in helping businesses bring their ideas to life quickly and efficiently. By utilizing advanced technologies and techniques, these services enable companies to create prototypes of their products in a cost-effective manner. In this article, we will explore 10 common questions and answers about rapid prototyping services in none, Bas-Rhin.

A: Rapid prototyping services involve the creation of physical prototypes using 3D printing, CNC machining, or other additive manufacturing technologies.

A: Rapid prototyping services can help businesses reduce time-to-market, lower costs, and test product designs before mass production.

A: Common materials used in rapid prototyping include plastics, metals, ceramics, and composites.

A: Yes, rapid prototyping services can reduce waste by only producing the exact amount of material needed for each prototype.

A: The time it takes to create a prototype varies depending on the complexity of the design and the chosen manufacturing technology.

A: While rapid prototyping is ideal for creating prototypes, it may not be suitable for large-scale production due to its slower production speeds.

A: Industries such as automotive, aerospace, medical, and consumer goods can benefit greatly from rapid prototyping services.

A: Yes, rapid prototyping services can be cost-effective compared to traditional manufacturing methods, as they require less tooling and setup costs.

A: Research online, ask for recommendations, and compare quotes from different providers to find a reliable and experienced rapid prototyping service provider in none, Bas-Rhin.

Rapid prototyping services in none, Bas-Rhin, offer businesses a fast and efficient way to bring their ideas to life. By utilizing advanced technologies and materials, businesses can create prototypes of their products quickly and affordably. Whether you are in the automotive, aerospace, medical, or consumer goods industry, rapid prototyping services can benefit your business by reducing time-to-market, lowering costs, and testing product designs before mass production. If you are looking for a reliable provider of rapid prototyping services in none, Bas-Rhin, be sure to do your research, ask for recommendations, and compare quotes to find the best fit for your business needs.