Rapid prototyping services in St. George , Utah

Our rapid prototyping service, in St. George , Utah makes quality components for your needs.

Our rapid prototyping service, in St. George , Utah makes quality components for your needs.

Welcome to RuiYi, your premier rapid prototyping service provider in St. George. With a focus on CNC machining prototyping, sheet metal prototyping, and more, we offer a wide range of innovative solutions to bring your designs to life quickly and efficiently. Our team of experienced professionals is dedicated to delivering high-quality prototypes that meet your exact specifications and exceed your expectations. Whether you are working on a new product development project or need a prototype for testing and validation, we have the expertise and capabilities to help you succeed. Trust RuiYi for all your prototyping needs in St. George and experience the difference our precision and dedication can make for your project. Reach out to us today to learn more about how we can bring your ideas to reality.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 7500×3400×1200mm / 295×133.8×47 in. | 200×500 mm / 7.9×19.7 in. |

| Minimum Part Size | 3.5×3.5 mm / 0.13×0.13 in. | 2×2 mm 0.079×0.079 in. |

| Standard Tolerances | +/- 0.01 mm +/- 0.0004 in. | +/- 0.01 mm +/- 0.0004 in. |

| Dimension | Metals: ISO 2768-m Plastics: ISO 2768-c | |

| Standards | Description |

| Thickness wall | 1.0 mm |

| Layer height | 50 – 300 μm |

| Max. build size | 250 * 250 * 250 mm (SLA), 420 * 500 * 420 mm (SLS) |

| Tolerance | ± 0.5% |

| Dimension | Tolerance |

| Edge to edge, single surface / Edge to hole, single surface / Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface / Over formed part, multiple surface | +/- 0.030 inch |

| Angle | +/- 1° |

Vacuum casting, also known as silicone vacuum casting or polyurethane vacuum casting, is a rapid prototyping and low-volume manufacturing process used to create high-quality plastic parts.

| Standard | Description |

| Maximum build size | +/- 0.025 mm (+/- 0.001 inch) |

| Standard lead time | Up to 20 parts in 15 days or less |

| Accuracy | ±0.05 mm |

| Layer thickness | 1.5mm – 2.5mm |

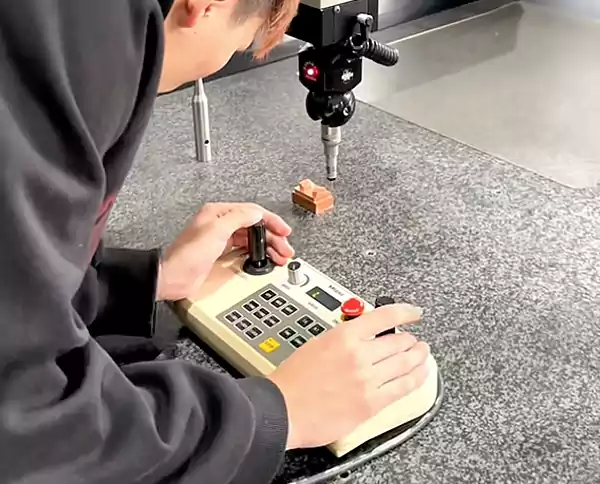

Upload your design to our quoting platform to receive instant, automated quotes along with a complimentary design analysis for your prototypes and production parts.

A design for manufacturability analysis will be completed for you within a few hours.

Once you place your order, we initiate the manufacturing process. Additionally, our digital platform provides real-time updates on the production stage.

After passing quality inspections, the parts are carefully packed for delivery. You can rest assured with our 30-day quality guarantee.

Allows manufacturers to create physical models of a product design to validate its form, fit, and function.

Enables quick iterations and modifications of a product design based on feedback and testing.

Creates prototypes that can be tested under real-world conditions to evaluate performance, durability, and functionality.

Facilitates the creation of custom and complex parts that might be difficult or impossible to using traditional manufacturing methods.

Creates prototypes of tools, jigs, and fixtures that are used in the manufacturing process to produce and assemble products.

Produces prototypes that can be used for market testing, customer feedback, and pre-production marketing.

Rapid prototyping services have revolutionized the way products are developed and tested in Utah. With cutting-edge technology and expertise, businesses can quickly bring their ideas to life and accelerate their time to market. This article will delve into 10 common questions about rapid prototyping services in Utah, providing insightful answers to help you better understand this valuable resource.

A: Rapid prototyping is a process that utilizes 3D printing technology to create physical prototypes of products or parts. This allows designers and engineers to quickly iterate on their designs, test functionality, and make necessary modifications before final production.

A: Rapid prototyping services in Utah offer numerous advantages, including faster development cycles, cost savings, improved product quality, and reduced time to market. By utilizing these services, businesses can stay ahead of the competition and bring innovative products to market more efficiently.

A: Various industries, such as aerospace, automotive, medical, and consumer goods, can benefit from rapid prototyping services in Utah. Whether developing new products or improving existing ones, rapid prototyping offers a valuable tool for innovation and success.

A: Rapid prototyping services in Utah offer a wide range of materials, including plastics, metals, ceramics, and composites. These materials can be tailored to meet specific design requirements and performance needs, ensuring the final product meets the desired specifications.

A: The time it takes to create a prototype can vary depending on the complexity of the design, size of the part, and chosen material. In general, rapid prototyping services in Utah can produce prototypes in a matter of days or weeks, significantly faster than traditional manufacturing methods.

A: Design software, such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing), is commonly used in rapid prototyping services in Utah. These software tools allow designers to create detailed and accurate models that can be easily translated into physical prototypes.

A: Rapid prototyping services in Utah are typically cost-effective, especially when compared to traditional manufacturing methods. By reducing material waste, labor costs, and production time, businesses can save money and resources while still producing high-quality prototypes.

A: While rapid prototyping is primarily used for small-batch production and prototyping, some services in Utah offer capabilities for larger-scale production runs. By leveraging advanced technologies and processes, businesses can scale up production as needed without sacrificing quality or efficiency.

A: Businesses in Utah can get started with rapid prototyping services by reaching out to experienced providers in the area. By consulting with experts, discussing project requirements, and collaborating on design concepts, businesses can kickstart their prototyping process and bring their ideas to life.

A: When choosing a rapid prototyping service in Utah, businesses should consider factors such as experience, technology, capabilities, cost, and turnaround time. By carefully evaluating these factors and selecting a reputable provider, businesses can ensure a successful prototyping process and achieve their product development goals.

In conclusion, rapid prototyping services in Utah offer a valuable resource for businesses looking to innovate, iterate, and accelerate their product development processes. By understanding the key aspects of rapid prototyping and leveraging the expertise of providers in the area, businesses can gain a competitive edge and bring their ideas to market faster than ever before.