Custom CNC machining services For Your Idea

On Demand Manufacturing

- Material: Al alloy, brass, stainless steel, and etc.

- Geometric Tolerances: +0.01mm/100mm

- Largest Size:3000*1200*850mm

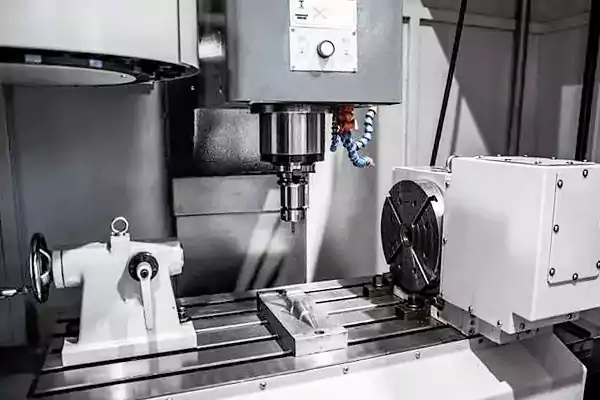

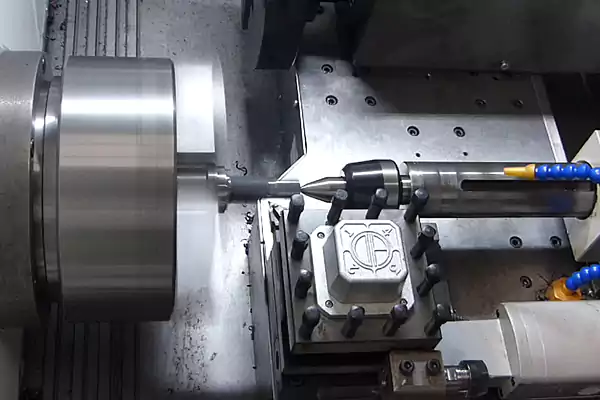

CNC Machining Services

CNC milling conducts multi-axis operations, encompassing 3, 4, and 5-axis machining processes, providing precision and enabling the crafting of intricate geometries from metal or plastic blocks.

CNC turning utilizes CNC lathes and turning centers to shape metal rod stock, specializing in the production of cylindrical parts. Our process guarantees uniform dimensions and impeccable surface finishes for all components.

How Ruiyi Works for you

Get Instant Quote

Upload your drawings to our quotation platform and we respond to most requests for quotations within 1 day.

Start Production

Once you place an order, we will start the production process, ensure the quality of the products, and keep you informed of production progress

Receive Your Parts

Fast air delivery and after-sales service follow up ensures order fulfillment.

Examples of Project Manufacturing

CNC Machining Matel Materials

Aluminum

Aluminum, with its high ductility, is effortlessly machinable. Featuring a commendable strength-to-weight ratio, this versatile material comes in various types suitable for a wide array of applications.Lead Time: < 10 days

Cooper

Copper exhibits outstanding thermal and electrical conductivity, as well as remarkable plasticity. Moreover, it boasts high ductility, resistance to corrosion, and ease of welding.Lead Time: < 10 days

Brass

Brass possesses favorable attributes suitable for various applications, including low friction, superb electrical conductivity, and a distinctive golden appearance.Lead Time: < 10 days

Stainless steel

Stainless steel is favored in CNC machining due to its impressive strength, durability, and resilience. Throughout the machining process, this material undergoes precise cutting, shaping, and drilling using various cutting tools such as drills, mills, and lathes.Lead Time: < 10 days

Titanium

Titanium stands out as a prized metal in CNC machining, valued for its silvery-white hue and lightweight nature. Its strength, durability, and corrosion resistance render it an exceptional choice. Yet, manipulating titanium in CNC machining demands adept skill and precision to fulfill precise specifications.Lead Time: < 10 days

Carbon steel

Carbon steel, extensively utilized in CNC machining, is renowned for its notable strength, hardness, and durability. Its elevated carbon content improves machinability during CNC operations, ensuring the production of precise and consistent parts.Lead Time: < 10 days

Tool steel

Tool steel is extensively employed in manufacturing molds for injection molding processes and serving as cutting implements, encompassing drills, end mills, and lathe tools. Its capacity to endure high temperatures, mechanical strains, and repetitive cycles positions it as an optimal selection for diverse industrial uses.Lead Time: < 10 days

CNC Machining Plastic Materials

ABS

ABS, composed of three monomers—acrylonitrile, butadiene, and styrene—possesses a distinctive array of qualities, such as exceptional impact resistance, effective heat resistance, and outstanding dimensional stability.

PMMA

PMMA, commonly referred to as acrylic, is a durable and transparent substance that withstands UV radiation and weathering. Its versatility allows for easy coloring, shaping, and utilization across a wide range of construction applications, owing to its appealing aesthetics.

PF

PF is a thermosetting plastic that has been widely used in electronic products, automobiles, aerospace, medical equipment and other fields due to its excellent physical, mechanical and chemical properties.

PC

Polycarbonate, a robust and resilient plastic, exhibits flame-retardant and antioxidant characteristics. Renowned for its outstanding impact resistance, transparency, and mechanical attributes.

PA

PA has good comprehensive properties, including mechanical properties, heat resistance, wear resistance, chemical resistance and self-lubrication. It has a low friction coefficient, has certain flame retardancy, and is easy to process.

PP

Polypropylene (PP) showcases exceptional chemical resilience, a lofty melting threshold, and minimal density. When employing CNC machining on PP, employing a sharp cutter with an elevated front angle and reduced cutting speed is imperative. These precautions thwart material overheating and melting.

PEEK

Polyetheretherketone (PEEK), an extraordinary engineering thermoplastic, is renowned for its remarkable attributes, such as exceptional resistance to high temperatures, inherent self-lubrication, ease of processing, and unparalleled mechanical robustness.

POM

Polyoxymethylene (POM), a thermoplastic substance, is celebrated for its elevated stiffness, minimal friction, ease of machining, and remarkable dimensional stability. Nevertheless, the machining process of POM presents challenges, attributable to its heightened melting threshold and susceptibility to chipping or cracking when cutting parameters are not meticulously managed.

PVC

PVC, robust and resilient, exhibits resistance to chemicals, weather, and fire. Nonetheless, machining PVC can generate hazardous dust and fumes, posing risks to workers’ safety. To ensure the well-being of workers, employ appropriate safety gear and implement adequate ventilation measures during the machining procedure.

PTEE

PTEE has high strength, high stiffness and excellent high temperature resistance. Its resistance to wear and chemical attack is also excellent. Compared with other engineering plastics, ptee has a lower friction coefficient and good self-lubricating properties.Surface Finishes

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing, a surface treatment method, embellishes workpieces with decorative lines achieved by grinding, culminating in a stunning and aesthetically pleasing finish. | Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin |  |

| Sand Blast | Sandblasting employs high-speed sand flow to cleanse and roughen a product's surface, aiming to attain precise levels of cleanliness and variable roughness on the workpiece surface. | All Metal Materials, Plastic | N/A | Matte |  |

| Tumbling | Tumbling involves placing materials in a rotating drum or container along with abrasive media for a surface treatment process. This action smoothens surfaces, removes burrs from edges, and enhances uniformity. | All Materials | N/A | Smooth, Matte |  |

| Polishing | Polishing, a mechanical surface treatment method, employs abrasives or buffing wheels to eliminate imperfections, refine surfaces, and elevate the appearance of materials, resulting in a glossy and reflective finish. | All Materials | N/A | Smooth |  |

| Anodizing | Anodizing is a surface treatment technique specifically designed for aluminum and its alloys. It generates a protective layer that enhances corrosion resistance, wear resistance, and hardness, simultaneously altering the material's surface appearance. | Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc | Smooth, matte finish. |  |

| Painting | Mount the product onto the rotating bracket and securely fasten the bracket onto the assembly line. Apply the paint evenly across the product's surface. While this process improves the product's tactile sensation, it may also render it vulnerable to scratches. | All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured |  |

| Black Oxide | Black oxide, an oxide film primarily employed to augment product corrosion resistance and appearance, simultaneously diminishing light reflection, proves highly effective for treating surfaces of steel and stainless steel. | Steel, Stainless Steel | Black | Smooth, matte |  |

| Electroplating | Electroplating serves functional, decorative, and corrosion-related functions, and is widely utilized across diverse industries. For example, the automotive industry frequently utilizes chrome-plating for steel automobile components. | Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |  |

| Powder Coating | Powder coating is a method of applying dry powder onto metal surfaces, usually via electrostatic means. Subsequently, the coated metal undergoes curing through either heating or exposure to ultraviolet light, resulting in a resilient and visually appealing finish. | Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss |  |

| Alodine | An alodine finish is a conversion coating method applied to aluminum parts, forming a thin protective film that effectively prevents corrosion. Additionally, it functions as a primer for subsequent painting processes. | Aluminum, Stainess Steel | Clear, Gold | As machined |  |

| Passivation | Passivation is a process applied to stainless steel to bolster its corrosion resistance. This entails submerging the metal in an acid solution to eliminate contaminants and promote the formation of a protective oxide layer on the surface, thereby averting rust and corrosion. | Stainess Steel | N/A | Matte |  |

| Electroless Plating | Electroless plating is a chemical process that deposits metal onto a substrate without the need for an external electrical current. This method initiates a catalytic reaction between the substrate and a metal ion solution, resulting in the formation of a uniform and strongly adherent coating. | Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |  |

CNC Machining Tolerances

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 7500×3400×1200 mm 295×133.8×47 in. | 200×500 mm 7.9×19.7 in. |

| Minimum Part Size | 3.5×3.5 mm 0.13×0.13 in. | 2×2 mm 0.079×0.079 in. |

| Minimum Feature Size | Φ 0.50 mm Φ 0.00197 in. | Φ 0.50 mm Φ 0.00197 in. |

| Standard Tolerances | Metals: ISO 2768-m Plastics: ISO 2768-c | Metals: ISO 2768-m Plastics: ISO 2768-c |

| Linear Dimension | +/- 0.01 mm +/- 0.0004 in. | +/- 0.01 mm +/- 0.0004 in. |

| Hole Diameters (Not Reamed) | +/- 0.01 mm +/- 0.0004 in. | +/- 0.01 mm +/- 0.0004 in. |

| Shaft Diameters | +/- 0.01 mm +/- 0.0004 in. | +/- 0.01 mm +/- 0.0004 in. |

| Edge Condition | Sharp corners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

| Ruiyi can manufacture threads to any specification and size required by our customers. | ||

| Text | Minimum width of 0.5 mm, depth of 0.1 mm Ruiyi can utilize CNC engraving or laser carving to create standard text according to customers' requirements. | Ruiyi can employ laser marking to create standard text on CNC turned parts. |

| Lead Time | 5 business days | 5 business days |

CNC Machining Services near me

FAQ

What is CNC machining?

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed software controls machinery to produce precise parts and components from various materials.

What types of CNC machining services do you offer?

We offer CNC milling, CNC turning, 3-axis, 4-axis, and 5-axis machining, as well as EDM (Electrical Discharge Machining) and precision grinding.

What materials can you work with for CNC machining?

We work with metals like aluminum, steel, brass, titanium, and copper, as well as plastics such as ABS, polycarbonate, POM, and more.

What is your standard lead time for CNC machining projects?

Our lead time typically ranges from 3 to 10 business days, depending on the complexity and quantity of the project.

What is the maximum size of parts you can machine?

We can machine parts up to [insert dimensions, e.g., 1000mm x 500mm x 500mm] and handle components with tight tolerances.

Can you provide prototypes and low-volume production runs?

Yes, we specialize in both rapid prototyping and low-volume production, ensuring flexibility to meet your specific needs.

What tolerances can you achieve?

Depending on the material and part geometry, we can achieve tolerances as tight as ±0.01mm, even more.

Do you offer post-machining services like surface finishing?

Yes, we provide surface finishes such as anodizing, polishing, powder coating, plating, and more, depending on your requirements.

How do you ensure quality control?

We follow strict quality assurance protocols, including CMM (Coordinate Measuring Machine) inspections, dimensional checks, and material certifications.

Do you ship internationally, and what is your pricing model?

Yes, we ship globally with competitive pricing. Our pricing is based on material costs, machining time, complexity, and order volume.