CNC machining services in Düsseldorf , North Rhine-Westphalia

Our CNC Machining service, in Düsseldorf , North Rhine-Westphalia makes quality components for your needs.

Our CNC Machining service, in Düsseldorf , North Rhine-Westphalia makes quality components for your needs.

Welcome to RuiYi, your trusted partner in manufacturing, offering a full suite of rapid prototyping services to support all your product development needs.

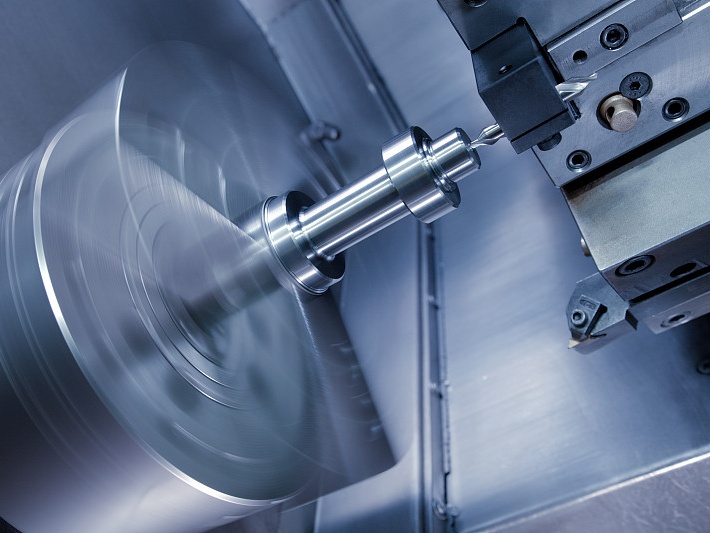

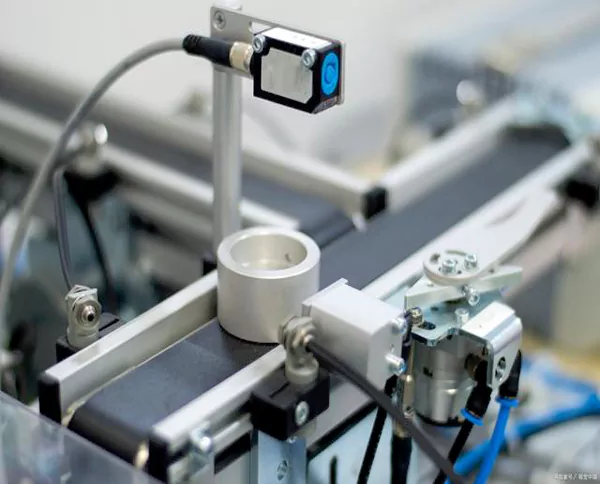

At RuiYi, we excel in CNC machining, providing precise and efficient prototyping solutions tailored to your unique project requirements. Our cutting-edge technology and team of skilled professionals guarantee high-quality results with every prototype.

Our CNC machining services use advanced equipment and software to create intricate and precise prototypes with speed and accuracy. Whether you require a single prototype or a small production run, our CNC machining capabilities are designed to handle projects of any scale or complexity. With additional expertise in sheet metal prototyping, vacuum casting, and 3D printing, RuiYi provides a complete range of services to bring your ideas to life.

CNC milling utilizes multi-axis capabilities, including 3, 4, and 5-axis machining, to achieve precise and intricate shapes from metal or plastic blocks, efficiently crafting intricate components with unparalleled accuracy.

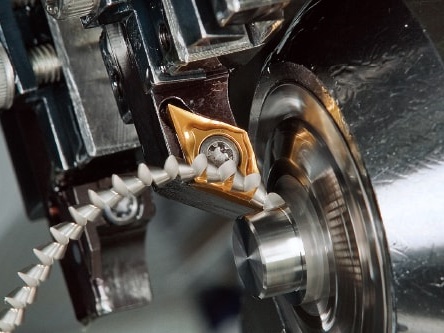

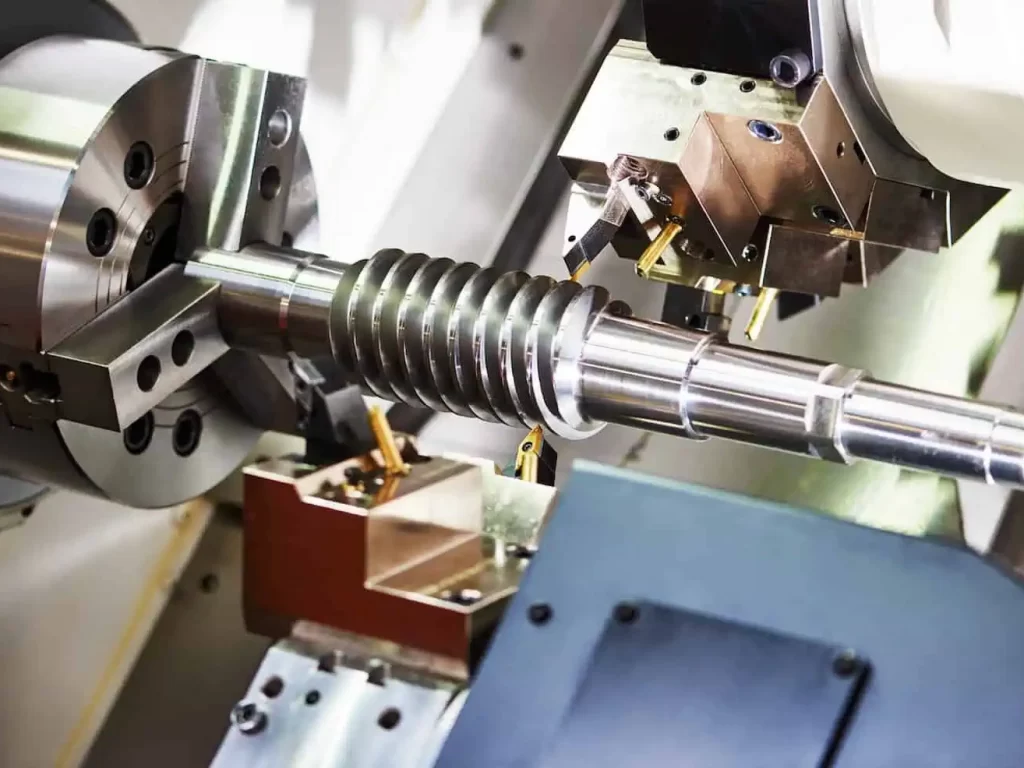

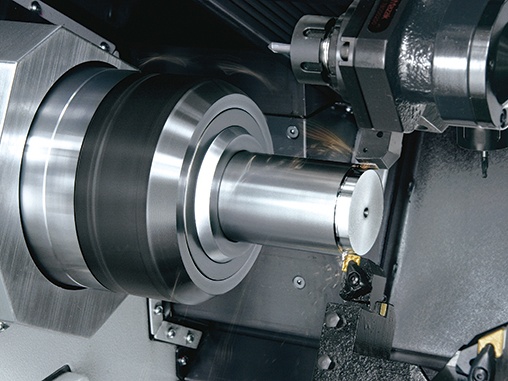

CNC turning uses CNC lathes and turning centers to shape metal rob stock, focusing primarily on cylindrical turned parts. Ensure components achieve consistent dimensions and smooth finishes.

A single-point cutting tool is advanced linearly, moving in a straight path alongside the rotational axis, within the confines of the preexisting hole's inner diameter.

Grooving, a form of CNC turning operation, entails the creation of a slender recess within the workpiece through the application of a specifically designed tool.

Parting is a manufacturing process that requires the use of a gouging technique to completely separate a section from the original workpiece.

This specific CNC turning method simplifies the process of forming grooves in workpieces, allowing for effortless screwing into other components.

This procedure involves intricately shaping the workpiece into a serrated design, aimed at improving the gripping ability of materials that necessitate heightened traction.

Taper turning is a machining process where a cylindrical workpiece is shaped by gradually reducing its diameter along its length, creating a tapered form.

Through programmed means, a form is sculpted around a fixed axis, steadily reducing the diameter to create a perfect spherical shape.

The machining process ensures uniform diameter reduction, preserving consistency throughout to prevent any deviations.

Q1: What services does RuiYi offer in the manufacturing and prototyping industry?

A1: RuiYi offers a broad range of prototyping services, including CNC machining, sheet metal prototyping, vacuum casting, and 3D printing. Our goal is to help clients move from concept to prototype quickly and accurately.

Q2: Why is CNC machining particularly suited for rapid prototyping?

A2: CNC machining is ideal for rapid prototyping because it provides high precision and efficiency. Controlled by CAD software, our CNC machines create detailed prototypes swiftly, ensuring that each part meets exact design specifications.

Q3: Does RuiYi handle custom prototype designs?

A3: Yes, RuiYi specializes in creating custom prototypes to meet unique project specifications. Our team has the expertise and technology to produce both simple and complex designs across various industries.

Q4: Which industries can benefit from RuiYi’s services?

A4: RuiYi serves clients in industries such as automotive, aerospace, medical devices, consumer electronics, and industrial manufacturing. Any industry requiring high-quality, precise prototypes can benefit from our services.

Q5: Does RuiYi offer options for both single and small-batch prototyping?

A5: Yes, RuiYi is equipped to handle both single prototypes and small-batch productions. We’re flexible in meeting different production needs, from one-off prototypes to small runs for testing and validation.

Q6: What is the advantage of RuiYi’s sheet metal prototyping?

A6: Sheet metal prototyping at RuiYi is ideal for producing durable, functional parts. This process is well-suited for industries that require robust metal components, and we ensure precision and strength in every piece.

Q7: How does RuiYi maintain quality in each prototype?

A7: RuiYi prioritizes quality by using advanced technology, precise software, and a skilled team. Every prototype undergoes thorough quality checks to ensure it meets the highest standards for accuracy, detail, and durability.

Q8: What is the difference between vacuum casting and CNC machining?

A8: Vacuum casting uses silicone molds to create flexible, detailed prototypes, which is great for small-batch production or complex parts. CNC machining, by contrast, uses rigid materials for high-precision parts and is typically best for creating strong, functional prototypes.

Q9: How quickly can RuiYi deliver prototypes?

A9: RuiYi’s rapid prototyping services focus on quick turnaround times, often delivering prototypes within days, depending on project complexity. Our goal is to help clients keep their projects moving forward efficiently.

Q10: Why choose RuiYi as your prototyping and manufacturing partner?

A10: RuiYi combines expertise in CNC machining, sheet metal, vacuum casting, and 3D printing, providing high-quality prototypes with fast delivery. Our full range of services and commitment to precision make us a trusted partner for all stages of product development.