CNC machining services in Virginia Beach , Virginia

Our rapid prototyping service, in Virginia Beach , Virginia makes quality components for your needs.

Our rapid prototyping service, in Virginia Beach , Virginia makes quality components for your needs.

Welcome to RuiYi, your premier rapid prototyping service provider in Virginia Beach. Specializing in CNC machining prototyping, sheet metal prototyping, and a variety of other cutting-edge techniques, we offer the perfect solution for bringing your product ideas to life quickly and cost-effectively. With our state-of-the-art equipment and skilled team of professionals, we can turn your concept into a high-quality prototype in no time. Whether you’re a startup looking to test a new design or an established company in need of a quick turnaround, RuiYi is here to help. Contact us today to learn more about how we can assist you in bringing your innovation to the market.

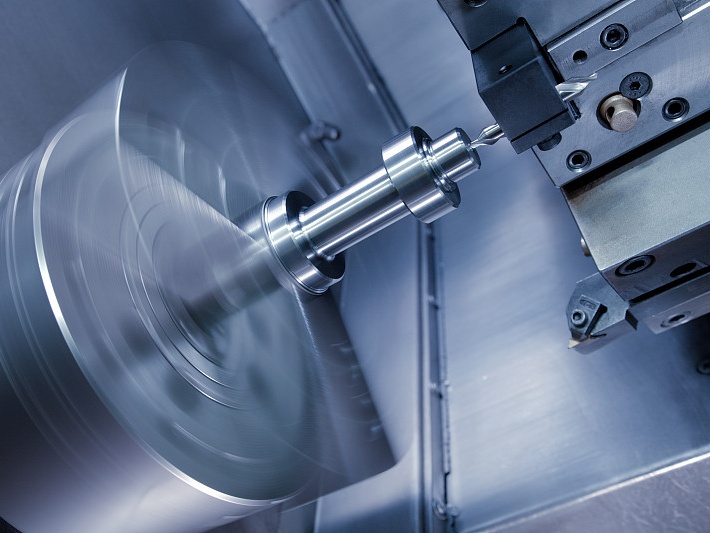

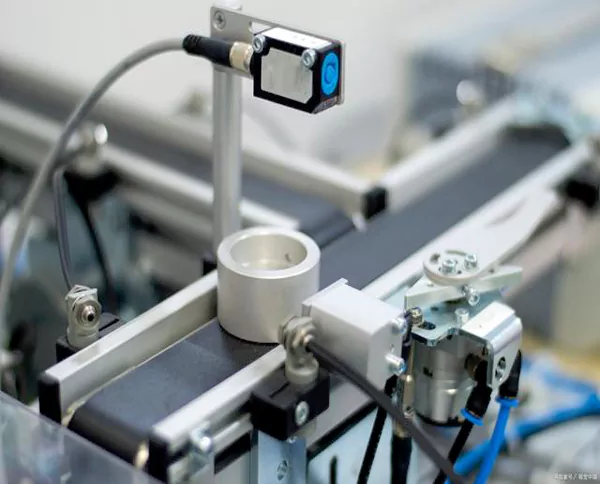

CNC milling utilizes multi-axis capabilities, including 3, 4, and 5-axis machining, to achieve precise and intricate shapes from metal or plastic blocks, efficiently crafting intricate components with unparalleled accuracy.

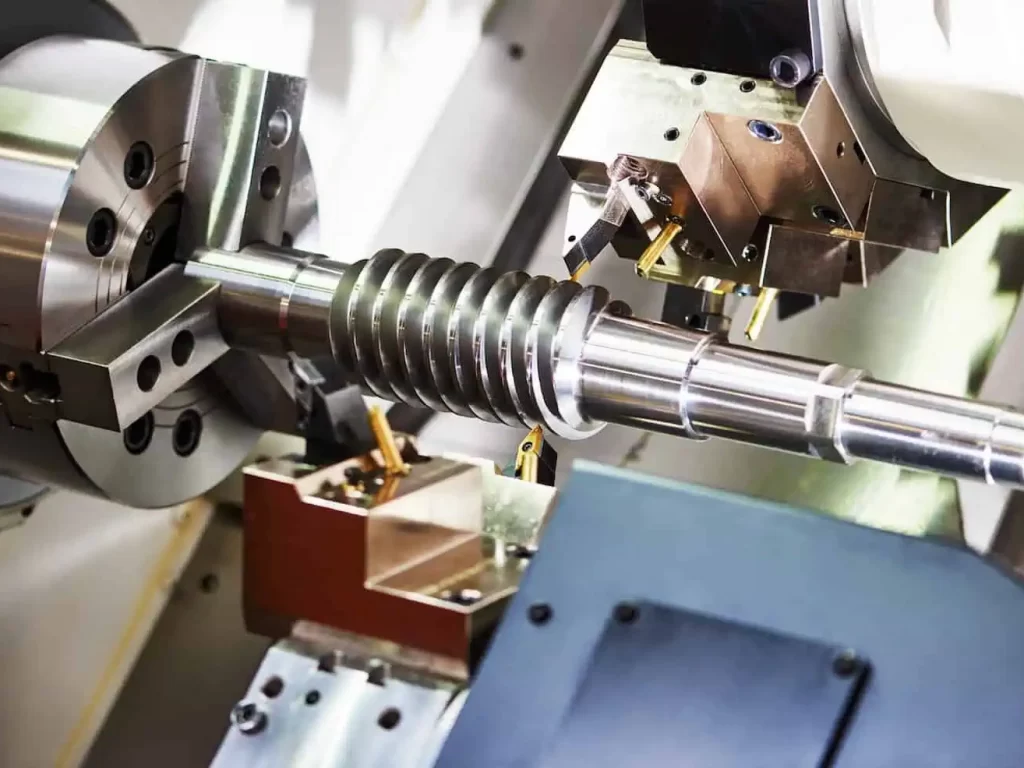

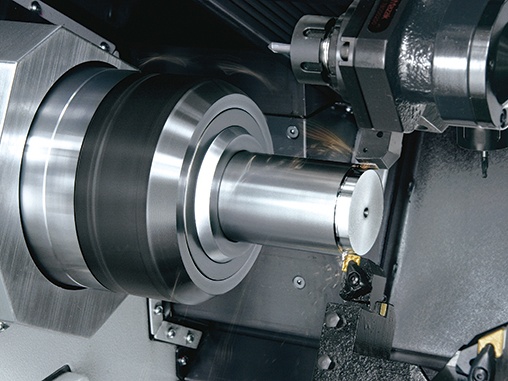

CNC turning uses CNC lathes and turning centers to shape metal rob stock, focusing primarily on cylindrical turned parts. Ensure components achieve consistent dimensions and smooth finishes.

A single-point cutting tool is advanced linearly, moving in a straight path alongside the rotational axis, within the confines of the preexisting hole's inner diameter.

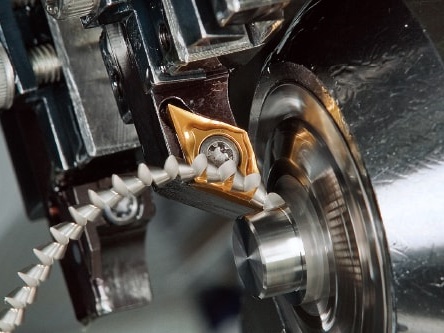

Grooving, a form of CNC turning operation, entails the creation of a slender recess within the workpiece through the application of a specifically designed tool.

Parting is a manufacturing process that requires the use of a gouging technique to completely separate a section from the original workpiece.

This specific CNC turning method simplifies the process of forming grooves in workpieces, allowing for effortless screwing into other components.

This procedure involves intricately shaping the workpiece into a serrated design, aimed at improving the gripping ability of materials that necessitate heightened traction.

Taper turning is a machining process where a cylindrical workpiece is shaped by gradually reducing its diameter along its length, creating a tapered form.

Through programmed means, a form is sculpted around a fixed axis, steadily reducing the diameter to create a perfect spherical shape.

The machining process ensures uniform diameter reduction, preserving consistency throughout to prevent any deviations.

Are you looking for CNC machining services in Virginia Beach, Virginia? Here are 10 commonly asked questions about CNC machining services in the area:

A: CNC machining is a manufacturing process that uses computer numerical control (CNC) systems to automate the operation of machine tools such as lathes, mills, routers, and grinders.

A: CNC machining can process a wide range of materials including metals (such as aluminum, steel, and titanium), plastics, wood, and composites.

A: CNC machining is very accurate, with tolerances as tight as +/- 0.005 inches depending on the material and complexity of the part.

A: Industries such as aerospace, automotive, medical, electronics, and defense benefit from CNC machining services due to the precision and repeatability of the process.

A: Look for a company that has experience in your industry, offers a range of machining capabilities, and has a reputation for quality and on-time delivery.

A: CNC machining offers fast turnaround times, high precision, complex shapes, and cost-effective production for small to large batch sizes.

A: Yes, many CNC machining service providers in Virginia Beach offer both prototyping and production capabilities to meet your specific needs.

A: Simply contact a CNC machining service provider in Virginia Beach with your project requirements, and they will provide you with a quote based on the complexity of the part and the volume of the order.

A: Lead times for CNC machining services in Virginia Beach can vary depending on the complexity of the part and the current workload of the service provider, but they typically range from a few days to a few weeks.

A: Yes, CNC machining services in Virginia Beach offer competitive pricing for high-quality machining services, making them a cost-effective option for your manufacturing needs.

Now that you have a better understanding of CNC machining services in Virginia Beach, Virginia, you can make an informed decision when choosing a service provider for your machining needs. Whether you need prototyping or production services, precision parts, or cost-effective solutions, CNC machining services in Virginia Beach can meet your requirements with quality and efficiency.