Table of Contents

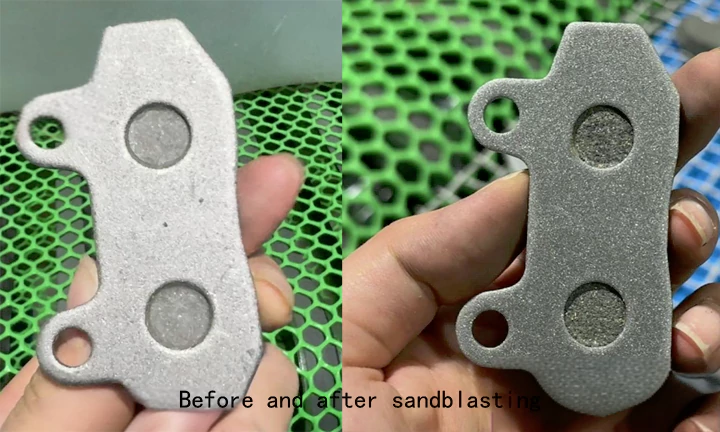

Sandblasting is a surface treatment process widely used in the machining industry and in prototyping hand boards. The process uses a high-speed jet of fine particles (such as sand or steel balls) to impact the surface of the workpiece, removing impurities and improving smoothness and aesthetics. Sandblasting not only removes rust, burrs, and defects but also creates a matte or textured decorative effect. Below are typical sandblasting roles in various fields:

Silicone Mold Sandblasting: Sandblasting removes tool lines from molds and prevents rust. It effectively smooths the mold surface by removing machining tool marks.

Fine Etching for Plastic Molds: This process engraves lines into plastic molds, adding delicate texture or bumpiness for decoration.

Oxidation Treatment: In oxidation factories, sandblasting helps create even, textured surfaces on metal workpieces. It reduces visual unevenness during oxidation.

Handpiece Production: Sandblasting removes burrs, paint, and machining marks in the handpiece manufacturing process. It improves the surface quality, ensuring smoothness and uniformity.

In my experience with handboard making, sandblasting enhances the surface details of workpieces, achieving higher aesthetics and precision.

Application Scope of Sandblasting

Sandblasting is not limited to metal materials. It is also used for plastic, glass, and ceramic surface treatment. Its main applications include:

Metal Descaling: Sandblasting removes rust and oxides from metal surfaces, restoring their original luster. It completely removes surface rust, enhancing the durability and aesthetics of the metal.

Aluminum Alloy Sandblasting: In industries like aviation and automotive, sandblasting improves the aesthetics, functionality, and corrosion resistance of aluminum alloys.

Glass Sandblasting: Sandblasting creates a matte effect on glass surfaces, enhancing their visual appeal. It is widely used in high-end appliances and architecture for decorative purposes.

Plastic Sandblasting: Sandblasting deburrs plastic products, smoothing them and removing production residue.

Acrylic Sandblasting: Sandblasting creates a matte finish on transparent acrylic pieces, reducing light reflection while enhancing aesthetics.

PC (Polycarbonate) Sandblasting: This process improves surface smoothness and decorative effect. It is common in lamps and automotive parts.

Sandblasting Material and Process Selection

The effectiveness of sandblasting depends not only on the equipment used but also on the choice of material. Different materials produce different surface effects. Choosing the right one is key to achieving the desired results.

1 .Acrylic Sandblasting

High Haze Requirement: For a strong atomization effect, use glass sandblasting or white corundum. These materials have strong friction that increases surface roughness, achieving high atomization.

Low Haze, High Transparency: Choose glass beads for better transparency. Their small particles provide a detailed atomization effect while maintaining transparency. To enhance translucency, customers may request mixing a small amount of glass sand with glass beads.

2.Stainless Steel Sandblasting

Material Selection: Sandblasting stainless steel requires selecting particles suited to the material. For polished alloy steel surfaces, or for tensile and atomized surfaces, choose materials based on the workpiece’s characteristics.

Low Roughness: For less smooth surfaces, use brown corundum or white corundum. These are effective for rougher surface treatment.

High Smoothness: For high smoothness, choose glass beads or glass sand. These materials provide delicate blasting effects and ensure a smooth, uniform surface.

3. Die Casting and Low Alloy Steel Blasting

Casting Steel Ball and Shot Blasting: Shot blasting machines use casting steel balls to clean surfaces. These balls are hard and effectively remove impurities and rust.

Aluminum Alloy Surface Treatment: For a whiter, cleaner aluminum surface, choose stainless steel shot or steel wire shot. These materials provide superior results, but they are more expensive. To reduce costs, use a mix of cast steel balls and continuous steel shot.

Summarizing

Sandblasting is an efficient, versatile surface treatment used across many industries. It removes impurities and improves both the aesthetics and functionality of workpieces.

Whether treating metal, plastic, or glass, selecting the right sandblasting process and material is crucial. By choosing appropriate materials and parameters, you can significantly improve the surface quality of the workpiece and achieve the desired results.