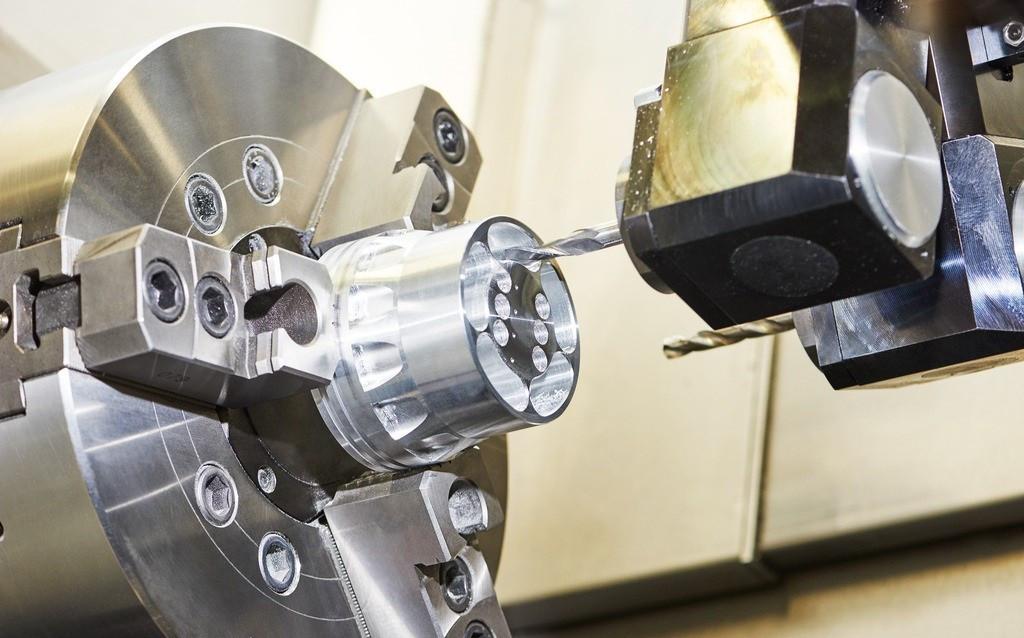

During the use of CNC machine tools, some small problems will inevitably occur, but these problems are not material and technical in themselves, but they are questions about whether the operation method is appropriate. For example, in the face of CNC screen problems How to avoid such problems? How to avoid it when buying and operating?  In order to avoid the problem of stuck screen in CNC turning and milling machining center, choose some products with high degree of machine automation as much as possible. This can effectively reduce the labor intensity of the machine itself. Many users are choosing such products, so they are very popular. Everyone is welcome.

In order to avoid the problem of stuck screen in CNC turning and milling machining center, choose some products with high degree of machine automation as much as possible. This can effectively reduce the labor intensity of the machine itself. Many users are choosing such products, so they are very popular. Everyone is welcome.  Only machines that can operate smoothly can show higher production efficiency, especially when everyone needs to produce in batches. Such machines are the most useful. When the problem of jamming has been successfully resolved, then Large-scale production can also be achieved, and the quality of the product can be significantly improved. These should be avoided by everyone when buying. CNC prototyping services by Ruiyi are professional, if you need, please send email to wuxingrui@ruiyimodel.com

Only machines that can operate smoothly can show higher production efficiency, especially when everyone needs to produce in batches. Such machines are the most useful. When the problem of jamming has been successfully resolved, then Large-scale production can also be achieved, and the quality of the product can be significantly improved. These should be avoided by everyone when buying. CNC prototyping services by Ruiyi are professional, if you need, please send email to wuxingrui@ruiyimodel.com

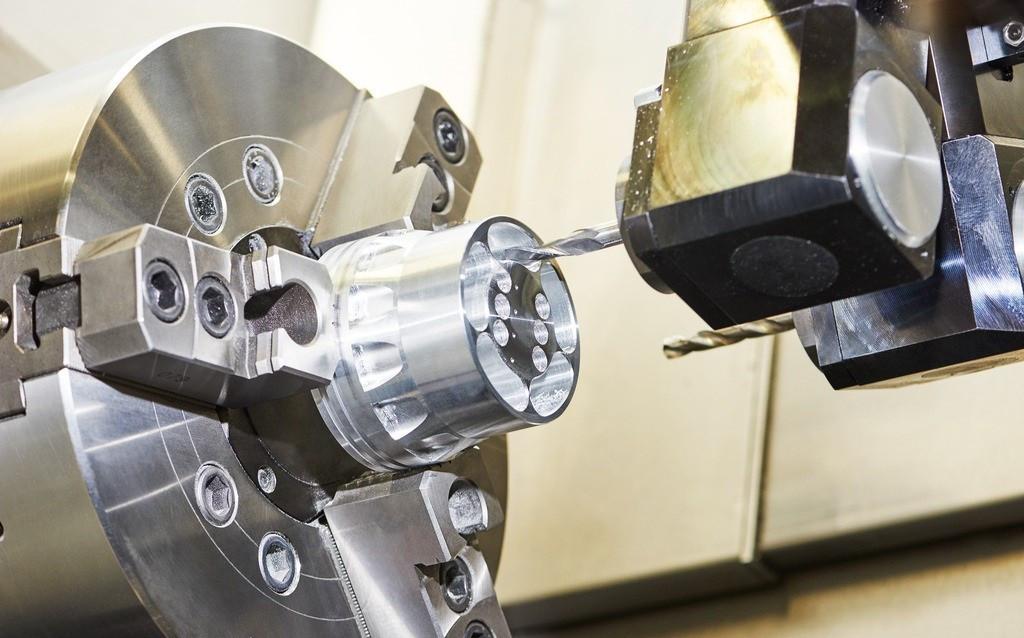

In order to avoid the problem of stuck screen in CNC turning and milling machining center, choose some products with high degree of machine automation as much as possible. This can effectively reduce the labor intensity of the machine itself. Many users are choosing such products, so they are very popular. Everyone is welcome.

In order to avoid the problem of stuck screen in CNC turning and milling machining center, choose some products with high degree of machine automation as much as possible. This can effectively reduce the labor intensity of the machine itself. Many users are choosing such products, so they are very popular. Everyone is welcome.  Only machines that can operate smoothly can show higher production efficiency, especially when everyone needs to produce in batches. Such machines are the most useful. When the problem of jamming has been successfully resolved, then Large-scale production can also be achieved, and the quality of the product can be significantly improved. These should be avoided by everyone when buying. CNC prototyping services by Ruiyi are professional, if you need, please send email to wuxingrui@ruiyimodel.com

Only machines that can operate smoothly can show higher production efficiency, especially when everyone needs to produce in batches. Such machines are the most useful. When the problem of jamming has been successfully resolved, then Large-scale production can also be achieved, and the quality of the product can be significantly improved. These should be avoided by everyone when buying. CNC prototyping services by Ruiyi are professional, if you need, please send email to wuxingrui@ruiyimodel.com