Rapid prototype China is an amalgamation of techniques used to develop a scale model of a physical part or assembly using 3D CAD data and other techniques. It is the basic need for starting production. Now, what is more important than anything else is selecting the best company that has been using advanced techniques and bringing you the latest solutions.

What technologies are used in rapid prototyping in China?

The selection of the best technologies and methods for a prototype depends on the featured product, machinery, or any concept still in imagination but ready to transform into reality. Some of the common technologies used in such prototype work include, but are not limited to:

1.3D Printing

Professionals widely use this method to create complex geometries and customized parts. The most common 3D printing technologies include FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering).

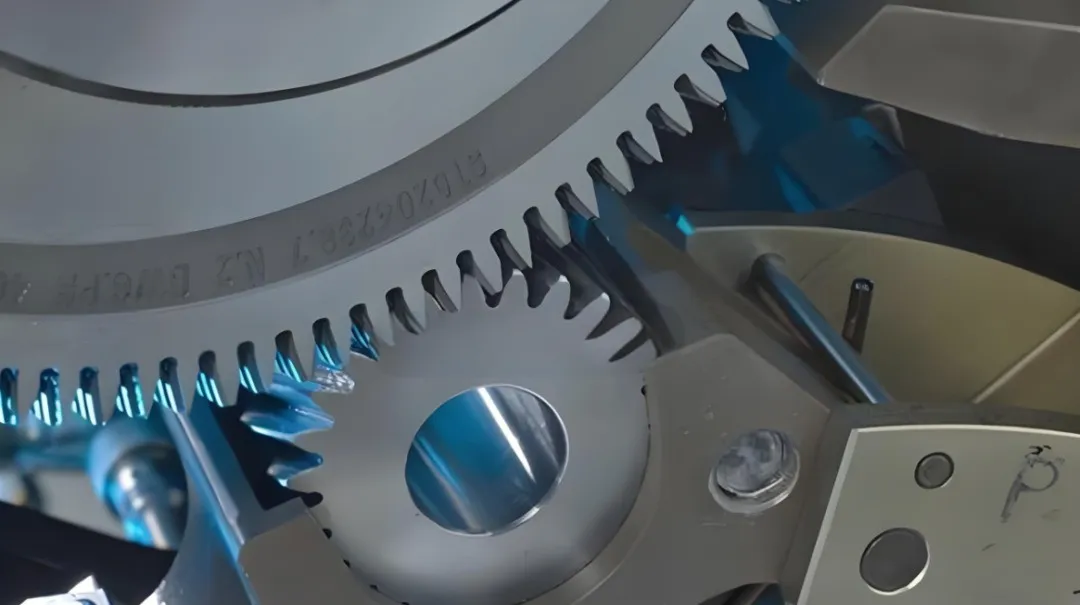

2. CNC Machining

CNC machining accurately produces high-strength and high-precision prototypes from metal and plastic materials, especially when the product requires high tolerances.

3 . Vacuum Casting

Vacuum casting helps produce small volumes of plastic parts. This method often creates prototypes that resemble the material of the final product. Technicians reproduce high-precision parts through silicone molds.

4.Injection Molding

Injection molding is suitable for high-volume production of prototypes. Manufacturers use an injection molding machine to inject molten material into the mold, where it cools and molds to form high-precision parts.

5.Sheet Metal Processing

Sheet metal processing mainly prototyped metal products through cutting, bending, stamping, and other processes. It is widely used for manufacturing shells, brackets, and other structural part.

6.Laser Cutting and Engraving

Laser technology cuts and engraves materials accurately, making it ideal for manufacturing complex two-dimensional structures and detailed part s.

7.Rapid Tooling

Rapid tooling techniques help create molds for low-volume production when a design needs conversion into a finished product as quickly as possible.

These technologies offer a wide range of choices for rapid prototyping in China and can meet needs from simple models to complex functional prototypes. When choosing a specific technology, consider factors like the design complexity of the product, material properties, functional requirements, and cost-effectiveness.

How to Get the Best of Rapid Prototype in China?

Getting the best rapid prototyping services in China requires a combination of key factors. China is home to a wide range of experienced and technologically advanced rapid prototyping companies that can provide a full range of solutions based on the needs of your industry. Here are some practical tips to help you choose the best prototype for your needs and ensure a successful project.

1. Define needs and goals

Before choosing a prototype builder, it is important to define your specific needs and project goals. This includes specific requirements for product functionality, material requirements, accuracy standards, and delivery times. Clearly defined project objectives will help you shortlist the most suitable suppliers.

2. Choose the right technology and material

Rapid prototyping manufacturers in China usually master a variety of technologies, such as 3D printing, CNC machining, vacuum casting, and so on. According to the complexity of your design, material properties, and the intended use of your prototype, choose the most suitable manufacturing process and material. This will not only improve the quality of your prototype but also optimize production costs.

3. Evaluate suppliers’ qualifications and experience

When screening suppliers, check their qualifications, certifications (e.g. ISO 9001), and past project experience. Find out if they have any success stories in your industry sector and examine their production facilities and equipment. All these factors have a direct impact on the accuracy and quality of the prototype.

4. Online search and supplier matching

Online searching is a convenient way to quickly learn about suppliers. By visiting company websites, reading customer testimonials, and viewing project examples, you can initially assess a supplier’s capabilities. In addition, communicating directly with suppliers and discussing your project requirements in detail via email, phone, or video conference ensures that they can meet your expectations.

5. Cost and budget management

While cost is an important consideration when choosing a supplier, it is important not to look at price alone. Cheap solutions may compromise on quality, service, or delivery times. Discuss your budget constraints with the supplier and make sure they can deliver a quality prototype solution within your budget. Compare quotes with multiple vendors and choose the most cost-effective solution.

6. Sample and prototype validation

Before finalizing your collaboration, ask the supplier to provide small batch samples or trial prototypes to verify their process capability and quality control level. By testing the samples, you can more visually assess whether they meet your standards and expectations.

7. Delivery cycle and logistics management

China’s manufacturing industry is known for its efficient production capacity and fast delivery. Before signing a contract, define the delivery schedule and find out if the supplier’s production program can meet your project schedule. In addition, consider logistics and customs clearance times to ensure that you deliver the prototype on time.

8. Intellectual Property Protection

Ensure that your designs and technology are fully protected during the collaboration. Sign a Non-Disclosure Agreement (NDA) with your suppliers and understand their policies and measures for IP protection. This is critical to prevent design leakage or unauthorized use.

9. After-sales service and support

A good supplier not only provides quality products but also provides timely technical support and after-sales service after the prototype is delivered. If problems arise during use, their ability to respond quickly and provide solutions directly affects the progress of your project.

10. Establish a long-term relationship

If you are satisfied with your supplier’s services and products, you can consider establishing a long-term relationship. Long-term cooperation not only improves the continuity and efficiency of the project but also optimizes the production process and cost through deeper communication and understanding.

Conclusion

Chinese rapid prototyping manufacturers can provide efficient, accurate, and competitive solutions to their global customers. By carefully selecting suppliers and managing all aspects of the process, you can ensure that your prototypes meet the highest standards, laying a solid foundation for mass production and marketing. No matter where you are in the world, it’s easy to reach out to China’s top suppliers for customized rapid prototyping services to bring your ideas and designs to life.