Machining is a method that alters the size and precision of raw materials to create components that meet design requirements.

From an academic perspective, machining is a structured, scientific method of material removal or shaping.

It uses precise cutting, grinding, or deformation techniques to produce functional parts with specific shapes and tolerances.

This process integrates principles of material science, mechanics, and advanced technologies.

According to Groover (2019) in Fundamentals of Modern Manufacturing, machining is defined as “a process that removes excess material from a workpiece using cutting tools to produce parts with desired geometry and surface finish.”

The ISO 9000 standard describes machining as “operations that achieve precise shapes, dimensions, and finishes by removing or deforming materials under controlled parameters.”

Machining accuracy measures how closely the actual dimensions match design requirements. Improved machining processes can boost accuracy, productivity, and product quality.

Machining Process

Machining is a vital stage in manufacturing that transforms raw materials into finished parts. It typically involves four steps:

Rough Processing: Initial machining like cutting or milling removes excess material and establishes the basic shape.

Fine Processing: Precision techniques like grinding or boring enhance accuracy and surface quality.

Inspection and Assembly: Measurements ensure parts meet specifications. Non-conforming parts undergo corrective actions.

Packaging and Shipping: Parts receive protective measures to prevent damage during transportation.

Factors Affecting Precision

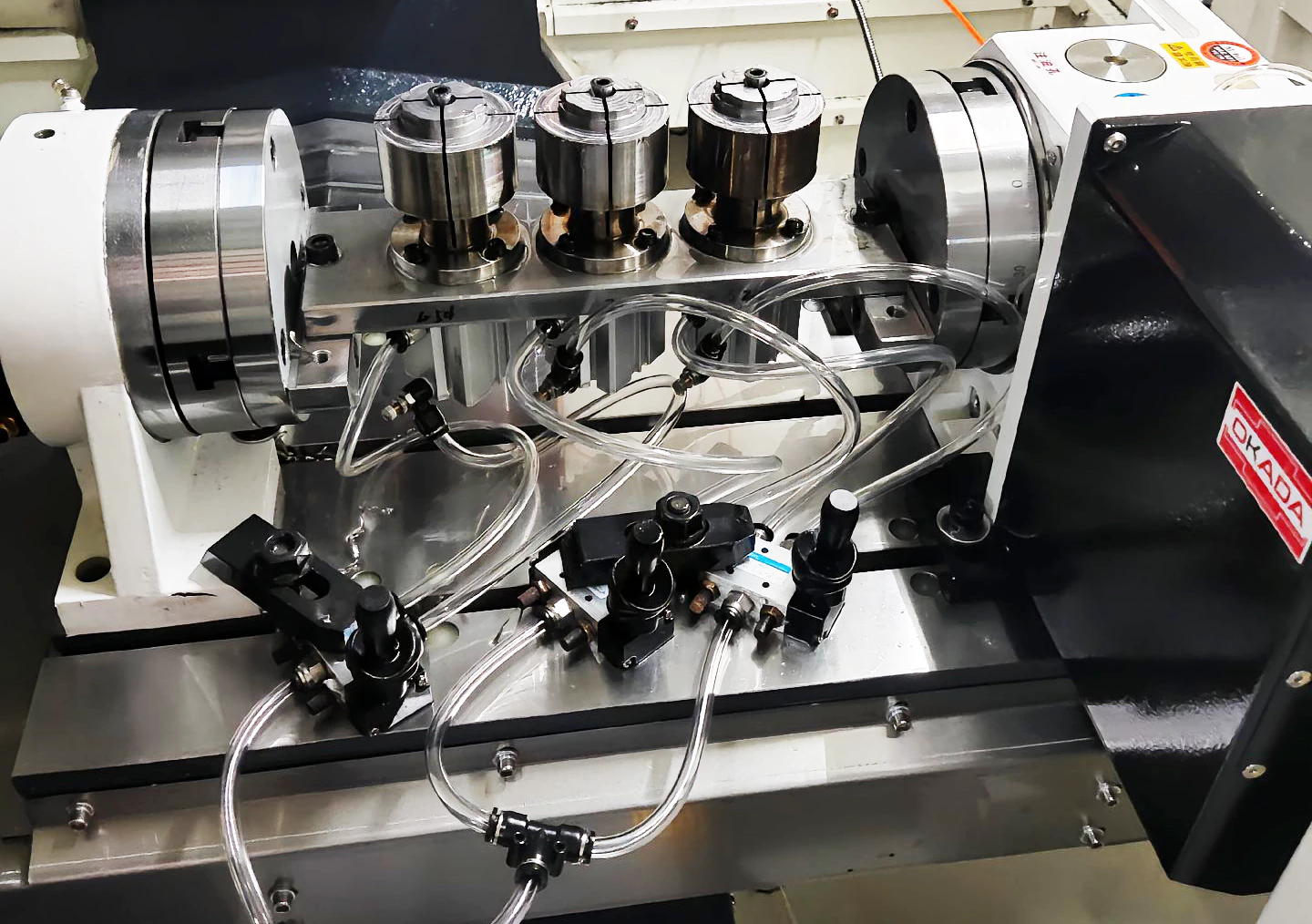

1. Machine Tool Accuracy

Machine tools are crucial for precise machining. Errors in control or transmission components affect accuracy. Regular calibration and maintenance are essential.

Machine stability and rigidity are also critical. Poor design can cause vibration or deformation, leading to size inaccuracies or rough surfaces.

High-precision machining requires quality coolant systems and temperature compensation to minimize thermal deformation caused by cutting heat.

2. Material Properties

Different materials, such as castings or aluminum alloys, have unique properties like hardness and thermal expansion.

Harder materials require robust tools and adjusted cutting depths for precision.

During machining, temperature changes can cause material expansion, affecting dimensions.

Design and production should account for these variations to minimize heat-induced errors.

3. Process Parameters

Process parameters include spindle speed, feed rate, and cutting depth. Incorrect settings may lead to tool wear, vibrations, and errors.

Coolant parameters also influence heat dissipation and temperature control, affecting precision.

Advanced CNC machines monitor and adjust parameters in real time to maintain accuracy and efficiency.

Measures to Optimize Machining Precision

1. Use Advanced Equipment

1.1 High-Precision Machines

Equip machines with reliable components like servo motors and guide rails. CNC systems like FANUC and Siemens optimize tool paths and improve efficiency.

1.2 Precision Measuring Tools

Accurate measuring tools enhance inspection reliability and support adjustments during machining. These tools include coordinate measuring machines and laser systems.

2. Select Efficient Tools

Choose tools based on material properties. Maintain tools regularly to prevent wear and deformation. For worn tools, regrinding or replacement ensures sustained accuracy.

3. Optimize Cutting Parameters

Set proper cutting and feed speeds based on material and tool properties. Incorrect speeds reduce efficiency or increase errors. Adjust speeds to balance precision and tool life.

4. Implement Online Monitoring

Real-time monitoring systems detect deviations and alert operators. They automatically adjust parameters to minimize errors, improving part quality and reducing waste.

5. Train Operators

Skilled operators directly impact precision. Training on equipment operation, material properties, and tool use ensures high accuracy and problem-solving capabilities.

For CNC operations, operators should learn programming, parameter selection, and toolpath optimization to enhance productivity and precision.

Conclusion

Improving the precision of mechanical machining processes is essential for achieving high-quality production and maintaining competitiveness in the manufacturing industry.

By optimizing machining processes through advanced equipment, precise tools, and effective operational strategies, manufacturers can significantly enhance product accuracy and production efficiency.

Key measures such as adopting high-precision machine tools, utilizing cutting-edge measurement systems, selecting efficient cutting tools, optimizing cutting parameters, implementing real-time monitoring, and providing comprehensive training to operators collectively contribute to minimizing errors and ensuring product compliance with design specifications.

Precision in machining is influenced by multiple factors, including machine tool accuracy, material properties, and machining parameters.

Systematic monitoring and control of these factors ensure consistent quality and improved productivity.

Furthermore, the integration of advanced technologies, such as online monitoring and feedback systems, supports proactive error correction, reduces waste, and enhances efficiency.

Ultimately, the success of machining processes optimization lies in a holistic approach that combines modern technology, skilled personnel, and robust process management.

This ensures not only improved precision but also long-term operational sustainability and customer satisfaction in the highly competitive manufacturing landscape.

What is the importance of precision in machining processes?

Precision ensures the final product meets design specifications, reduces material waste, and enhances the overall quality of the component.

Which machining parameters have the most significant impact on precision?

Key parameters include cutting speed, feed rate, depth of cut, tool geometry, and spindle speed.

How does tool wear affect product precision?

Tool wear can lead to dimensional inaccuracies, poor surface finish, and increased production defects over time.

What role does material selection play in achieving machining precision?

The machinability of the material affects the ease of cutting, tool wear rate, and surface quality, directly influencing precision.

How can CNC programming optimization improve machining precision?

Optimized programming ensures consistent tool paths, minimizes vibration, and reduces errors in cutting operations.

What is the impact of machine calibration on machining precision?

Regular calibration ensures the machine operates within specified tolerances, reducing errors and maintaining consistency.

How does coolant selection and application affect precision?

Proper coolant reduces heat, minimizes thermal deformation, and improves the surface finish, contributing to higher precision.

Can adopting advanced machining technologies enhance precision?

Yes, techniques like high-speed machining, 5-axis CNC, and adaptive machining improve accuracy by enabling complex geometries and reducing setup errors.

How can quality control measures ensure machining precision?

Implementing real-time monitoring, in-process inspections, and post-production quality checks helps detect and correct deviations early.

What are the common challenges in maintaining precision during mass production?

Challenges include tool wear, machine vibrations, thermal deformation, and material inconsistencies, which require robust monitoring and maintenance strategies.