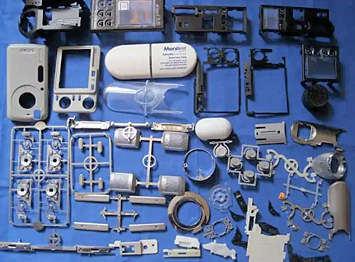

PC

PC is colorless glassy polymer, optically superior. High toughness of polymer resin, heat distortion temperature 130°C (140°C after glass fiber reinforcement). Flexural modulus exceeds 2400Mpa, can make large rigid products. Disadvantages: poor hydrolytic stability, not resistant to high pressure steam. Sensitive to chipping, poor scratch resistance, easy to yellow in the ultraviolet. But flame retardant, wear-resistant, anti-oxidation.PMMA

PMMA, a highly transparent thermoplastic, excels in weather resistance and UV stability, making it perfect for outdoor displays. With a light transmittance of 90%~92%, it’s more durable than glass. Its mechanical strength and toughness are high, making acrylic sheets ideal for aviation, automotive, and advertising industries. They are used to create a variety of products, including display stands, gift boxes, and jewelry cases.POM

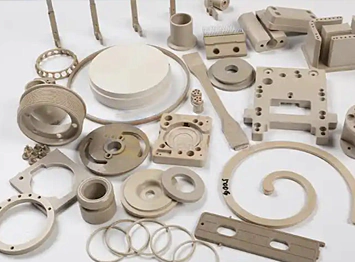

POM is a type of high-performance plastic characterized by its exceptional dimensional stability, minimal friction, and substantial strength. It finds widespread application in precision mechanical parts such as gears, bearings, and other components that endure high stress and require utmost accuracy.PA

PA(Nylon) is well-known for its robustness, adaptability, and resistance to wear, making it suitable for a diverse array of industrial uses such as gears, bearings, and automotive parts. Furthermore, it offers impressive resistance to abrasion and friction.PE

Polyethylene is a versatile, lightweight, and tough material resistant to impact, chemicals, and moisture. It has excellent low-temperature resistance down to -100~-70°C and good chemical stability, resisting most acids and alkalis. Although sensitive to environmental stress and heat aging, it can be processed by thermoplastic molding. PE is widely used in packaging, containers, piping, and as electrical insulation for TVs and radars, showcasing its diverse applications.PEEK

PEEK is a semi-crystalline, high-performance thermoplastic known for its exceptional heat resistance up to 260°C, mechanical strength, and chemical corrosion resistance. Despite its high cost and processing temperature, it has low UV resistance and can be corroded by certain acids. PEEK is widely used in aerospace, automotive, and medical fields, including aircraft engines, automobile parts, heating elements, artificial joints, and electronic connectors, due to its outstanding performance at extreme temperatures.HDPE

HDPE is a highly crystalline, non-polar thermoplastic with a density of 0.940~0.976g/cm³. It offers excellent strength-to-density ratio, durability, and impact resistance, making it suitable for harsh environments. Despite its poor air permeability, easy deformation, and surface hardness, HDPE is widely used in manufacturing bottles, piping, plastic lumber, packaging films, ropes, and other daily necessities due to its acid and alkali resistance, organic solvent resistance, and electrical insulation.HIPS

HIPS is a high-performance polystyrene plastic known for its ease of processing, good impact resistance, and dimensional stability. It has excellent physical properties, including high strength, toughness, wear resistance, and chemical resistance. HIPS is widely used in packaging, especially food containers, cups, lids, and trays, as well as disposable items like dishes, bottle caps, and pen holders.LDPE

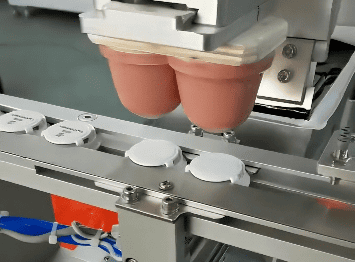

LDPE is a soft, flexible plastic with excellent sealing and heat-welding properties, commonly used in bags, tubing, and films. It has good forming performance, impact toughness, and can work at low temperatures. However, its mechanical strength, heat resistance, and environmental stress cracking resistance are poor. LDPE is widely applied in injection molding products, medical packaging, extruded pipes, and blow molding containers for dairy, jam, medicine, and cosmetics.PBT

PBT is a rigid, heat-resistant material widely used in automotive, electrical, and electronics applications. It has high heat resistance, toughness, and fatigue resistance, and maintains physical and electrical properties in humid environments. However, it has large volume resistance and electrical loss, and is susceptible to halogenated hydrocarbons. It crystallizes rapidly at low temperatures and has good formability, but low notched impact strength and high molding shrinkage. Reinforcement with glass fiber or inorganic filling can significantly improve its tensile, bending strength, and heat distortion temperature.PET

PET is a strong, chemical-resistant, and moisture-resistant thermoplastic polyol, used widely in food containers, beverage bottles, and textiles. It is milky white or light yellow with a smooth surface and high crystallinity. PET has good mechanical properties, high impact strength, and resistance to oils, fats, acids, alkalis, and solvents. It can withstand temperatures from -70C to 150C and has low gas and water vapor permeability, making it suitable for food packaging.PPS

PPS, a white powder thermoplastic, offers excellent chemical resistance, heat stability, and mechanical properties. With a specific gravity of 1.36 g/cm3 and molding shrinkage of 0.7%, it is ideal for automotive, aerospace, and industrial applications. PPS is used in high-temp, harsh chemical environments, replacing metal in parts like exhaust valves, pump bodies, and bearings, and is also suitable for structural, wear-resistant, and sealing materials.PS

PS, being lightweight and machinable, is frequently utilized for models, prototypes, and applications requiring low strength. Its ease of molding makes it a favorite choice for packaging and disposable products.PVC

PVC is a durable, cost-effective, and versatile material with strong chemical resistance. Its robustness and adaptability make it widely used in plumbing, medical devices, electrical cables, and construction materials.PTFE

Renowned for its superior chemical resistance and low friction characteristics, PTFE is frequently employed in non-stick coatings for cookware, gaskets for fluid sealing, seals in valves, and bearings in machinery. It excels in harsh conditions, enduring high temperatures and aggressive chemicals, such as in the chemical processing industry and aerospace applications.