Rapid prototyping services in Bouches-du-Rhône

Our rapid prototyping service, in Bouches-du-Rhône , makes quality components for your needs.

Our rapid prototyping service, in Bouches-du-Rhône , makes quality components for your needs.

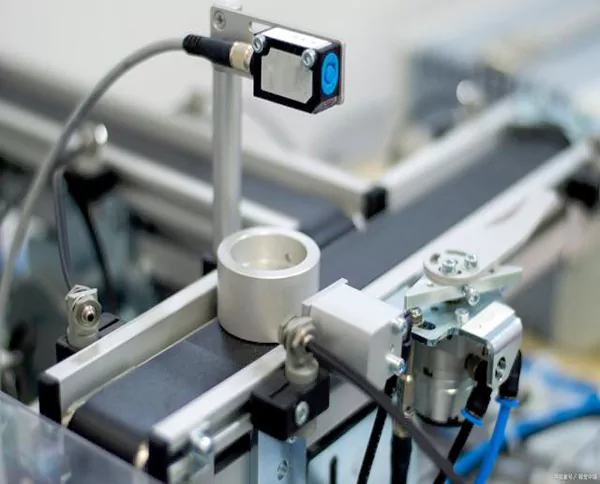

At RuiYi, we specialize in providing rapid prototyping services for a wide range of industries. As a leading manufacturing service provider, we offer CNC machining prototyping, sheet metal prototyping, vacuum casting prototyping, 3D printing prototyping, and other innovative solutions to bring your ideas to life quickly and efficiently. With our state-of-the-art technology and experienced team of professionals, we are dedicated to delivering high-quality prototypes that meet your exact specifications and requirements. Whether you are looking to test a new product design, develop a prototype for a presentation, or need a small batch production run, we have the capabilities and expertise to turn your concepts into reality. Our commitment to excellence and customer satisfaction sets us apart from the competition, as we strive to provide exceptional service and superior results on every project. With RuiYi as your rapid prototyping partner, you can trust that your ideas are in good hands and will be brought to fruition with precision and speed. Contact us today to learn more about our services and how we can help bring your next project to life.

optimal production method. CNC machining allows for the creation of precise prototypes with detailed accuracy and ensures completion within a short lead time.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 7500×3400×1200mm / 295×133.8×47 in. | 200×500 mm / 7.9×19.7 in. |

| Minimum Part Size | 3.5×3.5 mm / 0.13×0.13 in. | 2×2 mm 0.079×0.079 in. |

| Standard Tolerances | +/- 0.01 mm +/- 0.0004 in. | +/- 0.01 mm +/- 0.0004 in. |

| Dimension | Metals: ISO 2768-m Plastics: ISO 2768-c | |

During the product development process, we can use the flexibility of 3D printing for our customers to print a variety of products, tools, such as prototypes, jigs, fixtures and other manufacturing aids, and even rapid molds, such as molds for injection molding or thermoforming.

| Standards | Description |

| Thickness wall | 1.0 mm |

| Layer height | 50 – 300 μm |

| Max. build size | 250 * 250 * 250 mm (SLA), 420 * 500 * 420 mm (SLS) |

| Tolerance | ± 0.5% |

Leverage RuiYi’s efficient sheet metal processing to manufacture metal parts. Our state-of-the-art equipment and in-house production capabilities guarantee short lead times and rigorous quality standards.

| Dimension | Tolerance |

| Edge to edge, single surface / Edge to hole, single surface / Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface / Over formed part, multiple surface | +/- 0.030 inch |

| Angle | +/- 1° |

Vacuum casting, also known as silicone vacuum casting or polyurethane vacuum casting, is a rapid prototyping and low-volume manufacturing process used to create high-quality plastic parts.

| Standard | Description |

| Maximum build size | +/- 0.025 mm (+/- 0.001 inch) |

| Standard lead time | Up to 20 parts in 15 days or less |

| Accuracy | ±0.05 mm |

| Layer thickness | 1.5mm – 2.5mm |

Upload your drawings to our quotation platform and we respond to most requests for quotations within 1 day.

Once you place your order, we initiate the manufacturing process. Additionally, our digital platform provides real-time updates on the production stage.

Fast air delivery and after-sales service follow up ensures order fulfillment.

Enables manufacturers to create physical models of a product design to validate its form, fit, and function.

This allows for quick iterations and modifications of a product design based on feedback and testing.

Allows for the creation of prototypes that can be tested under real-world conditions to evaluate performance, and functionality.

Facilitates the creation of custom and complex parts that might be difficult or impossible to produce using traditional methods.

Allows for the creation of prototypes of tools, jigs, and fixtures used in the manufacturing process to produce and assemble products.

Produces prototypes that can be used for market testing, gathering customer feedback, and pre-production marketing.

Rapid prototyping services have become an essential part of the manufacturing industry in Bouches-du-Rhône, enabling companies to quickly bring their ideas to life. If you are considering utilizing these services for your next project, here are 10 common questions and answers to help you better understand the process.

A: Rapid prototyping is a process that involves quickly creating a physical model of a design using computer-aided design (CAD) software and 3D printing technology.

A: Rapid prototyping allows for faster iteration and testing of designs, reduces time to market, and enables cost-effective production of prototypes.

A: Bouches-du-Rhône offers a variety of rapid prototyping services, including selective laser sintering, stereolithography, and fused deposition modeling.

A: The time it takes to create a prototype depends on the complexity of the design and the chosen prototyping method, but it can typically range from a few hours to a few days.

A: Rapid prototyping materials vary depending on the chosen method and can include plastics, metals, ceramics, and composites.

A: Yes, rapid prototyping can be cost-effective for small businesses as it reduces the need for expensive tooling and allows for quicker validation of designs.

A: Prototypes created using rapid prototyping are highly accurate and can closely resemble the final product, providing valuable insights for design validation.

A: While rapid prototyping is primarily used for creating prototypes, it can also be utilized for short-run production of parts and components.

A: Some limitations of rapid prototyping include size restrictions, limited material options, and post-processing requirements for certain methods.

A: By utilizing rapid prototyping services, businesses in Bouches-du-Rhône can accelerate their product development process, reduce time and costs associated with traditional manufacturing methods, and gain a competitive edge in the market.

Rapid prototyping services offer a fast and cost-effective solution for bringing ideas to life in Bouches-du-Rhône. By understanding the process and benefits of rapid prototyping, businesses can take advantage of this technology to streamline their product development and gain a competitive advantage in the industry.