Rapid prototyping services in Waterbury , Connecticut

Our rapid prototyping service, in Waterbury , Connecticut makes quality components for your needs.

Our rapid prototyping service, in Waterbury , Connecticut makes quality components for your needs.

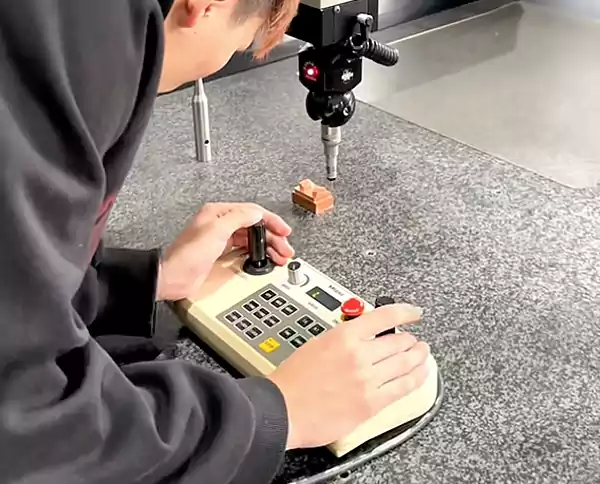

Welcome to RuiYi, your premier rapid prototyping service provider in Waterbury and beyond. With our state-of-the-art CNC machining prototyping and sheet metal prototyping capabilities, we are dedicated to helping you bring your design ideas to life with speed and precision. Whether you are a startup looking to create a prototype for investor presentations or a large corporation in need of a quick turnaround for product development, our experienced team is here to assist you every step of the way. From concept to production, RuiYi is your trusted partner in creating quality prototypes that meet your exact specifications. Contact us today to learn more about how we can help you turn your ideas into reality.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 7500×3400×1200mm / 295×133.8×47 in. | 200×500 mm / 7.9×19.7 in. |

| Minimum Part Size | 3.5×3.5 mm / 0.13×0.13 in. | 2×2 mm 0.079×0.079 in. |

| Standard Tolerances | +/- 0.01 mm +/- 0.0004 in. | +/- 0.01 mm +/- 0.0004 in. |

| Dimension | Metals: ISO 2768-m Plastics: ISO 2768-c | |

| Standards | Description |

| Thickness wall | 1.0 mm |

| Layer height | 50 – 300 μm |

| Max. build size | 250 * 250 * 250 mm (SLA), 420 * 500 * 420 mm (SLS) |

| Tolerance | ± 0.5% |

| Dimension | Tolerance |

| Edge to edge, single surface / Edge to hole, single surface / Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface / Over formed part, multiple surface | +/- 0.030 inch |

| Angle | +/- 1° |

Vacuum casting, also known as silicone vacuum casting or polyurethane vacuum casting, is a rapid prototyping and low-volume manufacturing process used to create high-quality plastic parts.

| Standard | Description |

| Maximum build size | +/- 0.025 mm (+/- 0.001 inch) |

| Standard lead time | Up to 20 parts in 15 days or less |

| Accuracy | ±0.05 mm |

| Layer thickness | 1.5mm – 2.5mm |

Upload your design to our quoting platform to receive instant, automated quotes along with a complimentary design analysis for your prototypes and production parts.

A design for manufacturability analysis will be completed for you within a few hours.

Once you place your order, we initiate the manufacturing process. Additionally, our digital platform provides real-time updates on the production stage.

After passing quality inspections, the parts are carefully packed for delivery. You can rest assured with our 30-day quality guarantee.

Allows manufacturers to create physical models of a product design to validate its form, fit, and function.

Enables quick iterations and modifications of a product design based on feedback and testing.

Creates prototypes that can be tested under real-world conditions to evaluate performance, durability, and functionality.

Facilitates the creation of custom and complex parts that might be difficult or impossible to using traditional manufacturing methods.

Creates prototypes of tools, jigs, and fixtures that are used in the manufacturing process to produce and assemble products.

Produces prototypes that can be used for market testing, customer feedback, and pre-production marketing.

Are you considering utilizing rapid prototyping services in Waterbury, Connecticut? Here are 10 common questions and answers to help guide you through the process.

A: Rapid prototyping is the process of quickly creating a physical model or prototype of a part or product using 3D printing technology.

A: Rapid prototyping allows for faster iteration and testing of designs, leading to quicker development cycles and ultimately cost savings.

A: Depending on the technology used, materials such as plastics, metals, and composites can be utilized in rapid prototyping.

A: The timeframe for rapid prototyping can vary depending on the complexity of the design and the chosen materials, but it is generally much quicker than traditional manufacturing methods.

A: Industries such as aerospace, automotive, medical, and consumer goods can all benefit from rapid prototyping services.

A: Research online reviews, ask for recommendations from industry colleagues, and inquire about the provider’s experience and expertise in rapid prototyping.

A: Costs can vary depending on the complexity of the design, the materials used, and the quantity of prototypes needed. It is best to request quotes from multiple providers to compare pricing.

A: Some limitations of rapid prototyping include size restrictions, material choices, and surface finish quality. It is important to consider these factors when utilizing rapid prototyping services.

A: Rapid prototyping allows for quick and cost-effective testing of design concepts, helping to identify and address potential issues early in the development process.

A: Rapid prototyping can reduce waste through additive manufacturing processes, as well as lessen the need for multiple iterations of physical prototypes, ultimately leading to a more sustainable product development process.

By understanding these common questions and answers about rapid prototyping services in Waterbury, Connecticut, you can make informed decisions when considering this innovative technology for your business. Rapid prototyping offers numerous benefits and can significantly impact product development cycles, so it is worth exploring for businesses looking to stay ahead in today’s competitive market.