Table of Contents

In recent years, China has rapidly emerged as a global leader in the sheet metal working industry, providing cutting-edge precision machining and prototyping solutions.

Whatever your needs, the Chinese market has the right products. Let’s explore which ones best suit your needs.

Technological Advances Drive Manufacturing Change

As technology advances, China’s manufacturing industry achieves higher productivity and more precise machining.

Today, continuous advancements in precision sheet metal prototyping, fabrication, and assembly allow China’s industry to better meet global demand.

The Chinese manufacturing sector is actively using these technologies to provide innovative solutions.

Ruiyi Leads the Industry

Ruiyi is a leader in sheet metal fabrication in China. With cutting-edge equipment and top-tier craftsmanship, Ruiyi sets industry standards.

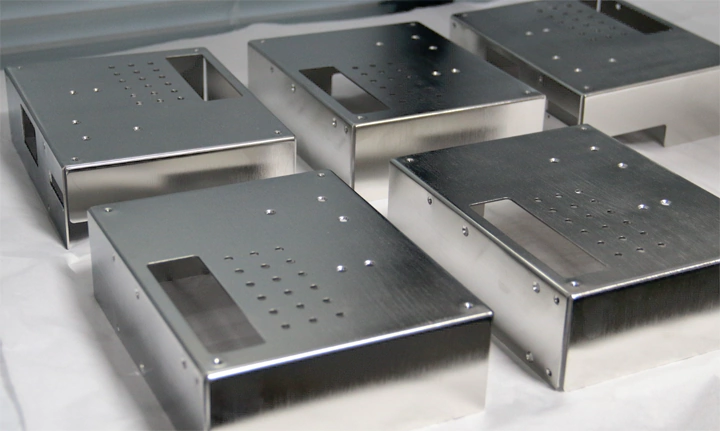

The company provides high-quality custom precision sheet metal prototypes, meeting all sheet metal fabrication and assembly needs.

Versatility of Sheet Metal Processing Materials

In sheet metal processing, almost any material can be used for prototyping, including common metals like aluminum, steel, and brass.

China’s industry can also handle materials like carbon steel, stainless steel, galvanized metals, beryllium copper, and nickel alloys. This diversity allows China to meet various customer needs.

Manufacturing Solutions for Diverse Needs

As demand for high-quality manufacturing solutions grows globally, many companies seek reliable partners.

Ruiyi offers efficient sheet metal fabrication services across industries, including electronics, medical, automotive, telecommunications, electrical appliances, computers, and industrial equipment.

Ruiyi also provides rapid tooling and injection molding services, enabling customers to quickly enter the market with molds tailored to their needs, material selection, production volume, and product specifications.

New Technologies in Global Manufacturing

Rapid tooling and injection molding are among the most effective technologies in global metal manufacturing.

Demand for these technologies grows as SLA rapid prototyping, vacuum casting, extrusion molding, and other methods evolve.

Choosing a manufacturer with years of experience and the ability to serve various industries is crucial.

Customer loyalty is also a key measure of a sheet metal fabrication shop’s quality.

Top manufacturers often have many repeat customers, reflecting their strength and service quality.