Table of Contents

Injection molding is a widely used process for mass production of complex parts. The process melts plastic raw materials through an injection molding machine, then injects them into the mold cavity at high pressure. After cooling and curing, it forms plastic products.

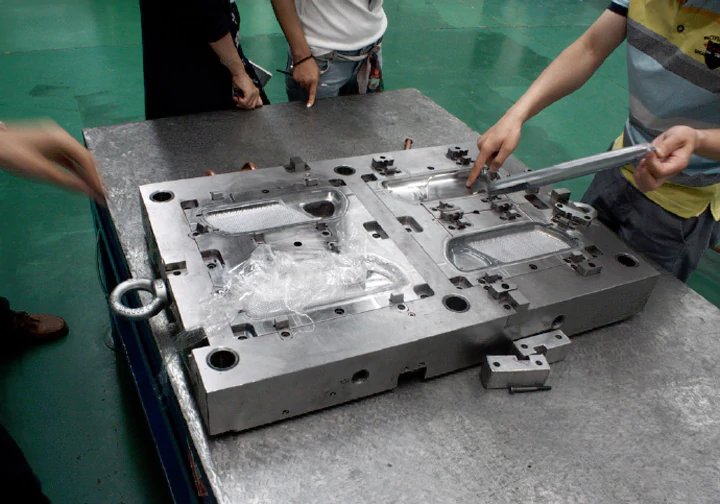

A plastic mold has two main parts: the moving mold and the fixed mold. The moving mold installs on the injection molding machine’s moving template, while the fixed mold installs on the fixed template. During injection, the moving and fixed molds close to form the casting system and mold cavity. When the mold opens, it separate, and workers remove the plastic products from the mold cavity.

Basic Structure of Injection Mold

The design of an injection mold depends on the plastic type, the product’s shape and structure, and the injection molding machine used. However, the basic structure remains similar and includes the following parts:

Pouring System: Injects molten plastic into the mold cavity.

Temperature Regulating System: Controls the mold temperature to ensure even cooling during molding.

Molding Section: Directly contacts the plastic, determining the shape and size of the final product.

Structural Part: Supports the overall mold structure, ensuring stability and reliability.

Pouring System and Molding Section

The pouring system and molding section are the most critical parts of an injection mold. These parts contact the plastic and change as it flows and cures. Due to their need for high machining accuracy, these parts are usually the most complex and variable in the mold.

Injection Molding Process

Injection molding is an efficient mmass-productionprocess. It creates precise dimensions and structural integrity in plastic products. The process injects molten plastic into high-precision mold cavities, then cools and cures it to form the final product.

Conclusion

The design and manufacture of injection molds are crucial for ensuring the quality and productivity of plastic products. Understanding the mold’s basic structure and process helps optimize production and improve product quality.