Table of Contents

Sheet metal processing plays a crucial role in modern manufacturing. Its quality directly impacts product performance and competitiveness. Let’s explore its key aspects and the factors influencing quality. This analysis, provided by Ruiyi Precision Processing Factory, aims to be helpful.

What is Sheet Metal Processing?

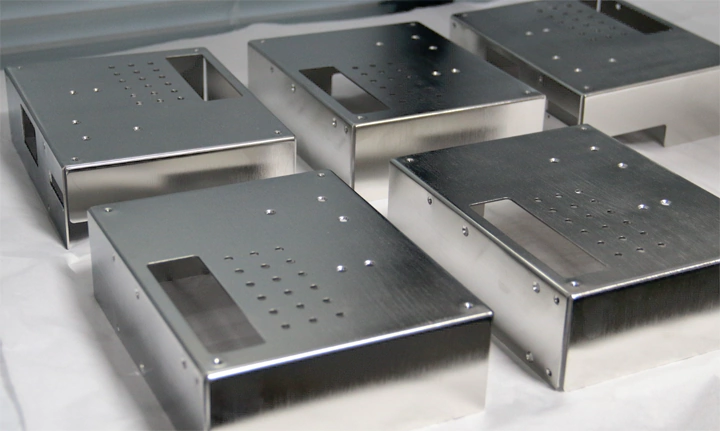

Sheet metal processing transforms sheet metal into various parts or finished products using cutting, bending, stamping, welding, and assembly. This method is commonly used in home appliance housings, automotive parts, industrial equipment covers, and architectural decorations.

Core Aspects of Sheet Metal Processing

1. Accurate Dimensions: Ensure parts meet design specifications and tolerances.

2 . Attractive Appearance: Surface treatments improve aesthetics and corrosion resistance.

3.Efficient Structure: Simplify processing and facilitate assembly.

Common Sheet Metal Processing Equipment

1.Cutting Equipment:

– Plate shears cut straight lines efficiently but have limited applications.

– Laser cutters handle complex shapes precisely with smooth results.

– Plasma cutters are ideal for thick plates requiring low precision.

– Water jet cutters use high-pressure water without altering material properties.

2.Molding Equipment:

– CNC punching machines excel at batch processing parts with holes.

– Bending machines shape sheets accurately based on angles and strength.

3.Auxiliary Equipment:

– Deburring machines enhance surface finishes by removing burrs.

– Leveling machines ensure sheet flatness by eliminating internal stress.

– Spot welding machines connect parts quickly.

The equipment’s quality and condition greatly affect the final product’s precision and efficiency.

Steps in Sheet Metal Processing

1. Material Selection: Choose sheets like cold-rolled steel, stainless steel, or aluminum based on design needs.

2. Cutting: Use precision tools to shape sheets per drawing, ensuring minimal errors.

3. Bending: Shape sheets accurately to avoid assembly issues.

4. Welding and Assembly: Join parts with controlled techniques for strong connections.

5 . Surface Treatment:

-Pre-treatment: Clean surfaces for better adhesion.

-Post-treatment: Paint or coat parts for durability and aesthetics.

6 . Quality Inspection: Verify dimensions, appearance, and function after each step.

Factors Influencing Sheet Metal Quality

1.Equipment Condition: Maintain machinery for precision and fewer defects.

2. Operator Skill: Experienced workers adjust parameters and control material deformation effectively.

3. Material Quality: Select suitable materials for the desired properties and processes.

4. Design Efficiency: Simplify designs to reduce production steps and costs.

5 . Environmental Control: Maintain optimal humidity and cleanliness, especially during surface treatments.

Ruiyi Precision Processing Factory’s Strengths

1. Advanced Machinery: Equipped with top-tier tools like laser cutters and CNC benders.

2. Skilled Team: Experts solve complex challenges and offer tailored solutions.

3 . Stringent Quality Checks: Dedicated inspectors ensure zero defects.

4. Custom Services: Meet diverse needs with personalized designs and processing.

Choose Ruiyi Precision Processing Factory for reliable sheet metal processing. Contact us for quotes and support to enhance your projects.

This guide highlights critical aspects of sheet metal processing and its quality factors. For more information, reach out to Ruiyi Precision Processing Factory!