Table of Contents

In modern manufacturing, the emergence of rapid prototyping technology has brought revolutionary changes to product design and development. Aluminum alloy rapid prototyping technology, with its unique advantages and flexibility, has become an essential tool for product designers in design verification and development. This article explores how it benefits product designers.

Basic principles of aluminum rapid prototyping

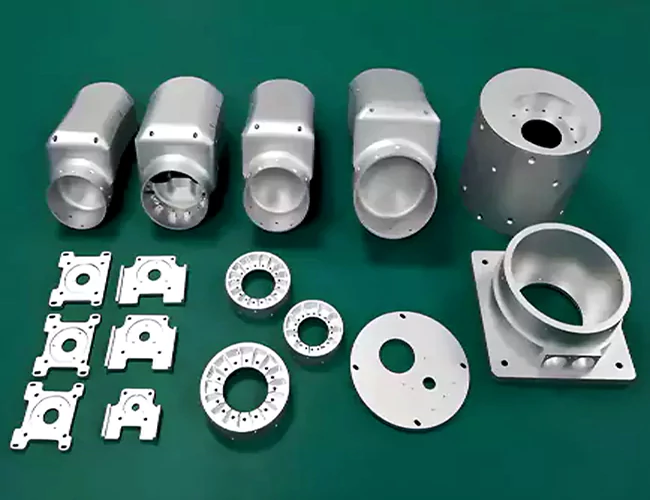

Aluminum rapid prototyping quickly transforms aluminum alloys into complex prototypes or products using technologies like CNC machining or 3D printing. Its key advantage is generating high-precision models directly from digital designs, eliminating mold-making time and costs and enabling innovative designs.

Benefits of aluminum alloy rapid prototyping technology for product design

1. Shorten the product development cycle

In a highly competitive market, the speed of product development often determines the success of a company. Aluminum alloy rapid prototyping significantly shortens the product development cycle, allowing designers to verify and optimize designs in less time. Traditional mold processing is time-consuming, and design errors require costly, multiple adjustments.

Aluminum alloy additive manufacturing quickly generates functional prototypes, allowing designers to rapidly test and iterate designs. In this way, products can be brought to market faster and meet the needs of customers and the market.

2. Improve the accuracy of design verification

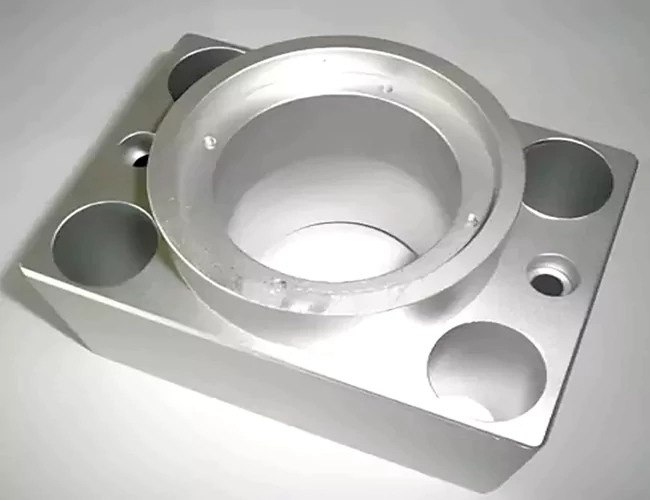

Design verification is crucial in product development, and aluminum alloy rapid prototyping plays a key role by offering prototypes with mechanical properties similar to the final product, providing more accurate verification results.

In the automotive or aerospace industries, designers must ensure parts function well in high-stress environments. Using aluminum alloy additive manufacturing prototypes, designers can test products in real environments and obtain more reliable performance data. This not only reduces the risk of design errors but also improves the quality of the final product.

3. Promote innovation and flexibility

Aluminum alloy additive manufacturing provides great design freedom, and designers can explore more innovative design solutions. Aluminum alloy additive manufacturing enables complex geometries and unique designs, unlike traditional processes limited by tools and materials.

This flexibility is ideal for prototyping and low-volume production, enabling designers to quickly test and select the best design. This not only inspires more creativity but also makes the product more unique and more competitive in the market.

4. Reduce production costs

Aluminum alloy rapid prototyping technology offers significant advantages in overall production costs, despite the higher material cost. Molds and tooling for traditional manufacturing processes are expensive, especially when producing in small batches. Aluminum alloy rapid prototyping uses CNC or 3D printing to process parts directly, saving on initial investment.

Aluminum alloy rapid prototyping’s high precision and consistency reduce material waste, control budgets, and allow more resources for product innovation.

5. Improve product performance and quality

Aluminum alloys are widely used in many industries due to their excellent properties. Additive manufacturing allows designers to create prototypes that are strong, corrosion-resistant, and thermally conductive, essential for final product performance and quality.

In consumer electronics, aluminum alloy prototypes simulate thermal characteristics, helping designers optimize structure and performance. In automotive and aerospace, aluminum alloy additive manufacturing ensures performance while reducing weight.

6. Support complex design and customization requirements

As market demands become increasingly diverse and personalized, product designers need to be able to respond quickly to customers’ customized needs. Aluminum alloy additive manufacturing technology enables rapid manufacturing of complex designs, whether complex geometries or multi-functional integrated components.

Aluminum alloy additive manufacturing enables quick, customized solutions and high-quality products with short lead times, boosting customer satisfaction and market competitiveness.

7. Environmentally friendly and sustainable

Environmental protection and sustainability are now crucial in modern manufacturing g. Aluminum alloy additive manufacturing technology excels in this regard. Aluminum alloy is a recyclable material, and during the production process, there is less material waste and lower energy consumption. This not only reduces the impact on the environment but also conforms to the concept of sustainable development.

Choosing aluminum alloy rapid prototyping enhances product performance, quality, and brand value while appealing to consumers with eco-friendly manufacturing.

8. Reduce resource waste

Aluminum alloy additive manufacturing offers clear advantages over traditional methods, as it produces parts layer by layer with minimal waste, helping companies save resources and costs.

Conclusion

Aluminum alloy rapid prototyping technology provides product designers with comprehensive support from design verification to production and manufacturing. Aluminum alloy rapid prototyping shortens R&D cycles, improves design accuracy, fosters innovation, and reduces costs.

With ongoing technological advancements, aluminum alloy rapid prototyping will offer designers more innovative possibilities, enabling the creation of competitive products that meet market and customer demands. This progress will drive innovation across industries and enhance product quality for consumers.