Table of Contents

With the rapid development of the economy and technology, customer demands for lathe processing accuracy have increased. CNC lathe technology has improved both the quality and efficiency of mechanical processing.

Various internal and external factors can affect CNC lathes, preventing them from meeting processing accuracy requirements. To ensure accuracy, operators should analyze these factors and adopt targeted prevention strategies.

Composition and working principle of CNC lathes

CNC lathes use advanced programs to stabilize the processing of rotating and shaft workpieces, improving quality and efficiency. Due to higher precision requirements for batch production, operators should use information technology tools like numbers, letters, and symbols to design automatic control programs, which are then input into the CNC lathe’s control system to ensure smooth processing.

After part processing starts, the CNC lathe operator collects and analyzes data, converts it into a digital or coded form, and the main control system processes it, issuing instructions to the actuator for normal operation.

After part processing, the CNC lathe’s main control system ensures each actuator returns to the initial position, improving processing precision. Since CNC lathe precision affects manufacturing quality and efficiency, professional technicians must write the CNC program to ensure smooth processing.

As information technology advances, the demand for higher production quality and precision in mechanical manufacturing increases. Traditional processing methods can no longer meet these demands, so companies should explore CNC machining strategies to improve accuracy and produce higher-precision products.

Quality factors affecting the machining accuracy of CNC lathes

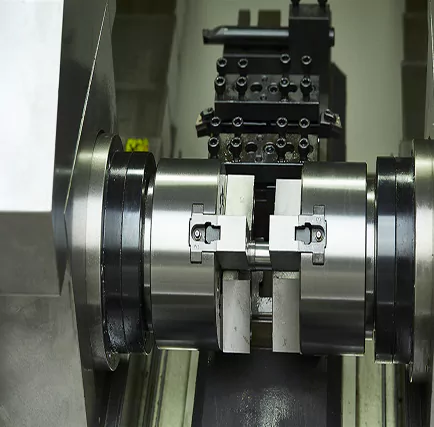

CNC lathe machining uses automated lathes to control part and tool movement via digital information. Machining accuracy refers to how closely the actual geometric parameters of the part match the ideal specifications in the drawing. The greater the consistency, the higher the machining accuracy. Many factors affect the machining accuracy of CNC lathes, mainly the following points.

1. Lathe quality factors

The machining accuracy of parts on CNC lathes is mainly affected by human factors, equipment, accidents, and other aspects. Among these, issues with the CNC lathe itself are critical. If the CNC system configuration is faulty, the workpiece may not meet accuracy standards. Therefore, operators must take measures to ensure the lathe’s stability and rigidity, preventing operational errors that could affect workpiece quality and accuracy.

2. Raw materials and error factors

Tool setting angles and measurement errors significantly affect machining accuracy during CNC lathe operation. Since CNC tools have specific size and angle requirements, operators select tools based on the processed material. However, tool size and angle can change during operation, and any deviation will impact machining accuracy.

According to relevant survey data, most of the CNC machine tools used in most mechanical processing companies in China currently use motors to drive ball screw transmissions to achieve feed. During the workpiece processing of CNC lathes, it is inevitable that there will be large gaps between the bearings under the influence of external forces, resulting in comprehensive errors on the front and back sides of the workpiece, affecting the machining accuracy of the workpiece and reducing the efficiency of CNC machining.

3. Cutting amount factor

Before processing a workpiece with a CNC lathe, the operator must select tools based on the part’s characteristics and requirements to ensure accuracy and quality. For example, the operator should consider cutting factors such as back cutting, feed rate, and spindle speed, and adjust strategies to meet design accuracy standards.

If the parts have strict accuracy requirements, the CNC lathe operator should choose a method that meets the required standards to ensure accuracy.

Measures to improve the processing accuracy of CNC lathes

1. Strengthen lathe maintenance management

To ensure efficient CNC lathe operation, operators must implement a window inspection and maintenance system, use the lathe’s built-in program to analyze processing data and replace necessary tools by detecting the spindle to maintain workpiece accuracy.

Operators should follow the inspection and maintenance system of CNC lathes, focusing on real-time monitoring, lubrication, oil levels, and sliding parts to improve efficiency.

During CNC lathe operation, the operator should regularly check for heating issues and clean debris from the filter. If the rotating device fails, stop the lathe immediately, clean the residue, and replace the filter to improve processing accuracy. Additionally, the operator should regularly check electrical plugs and sockets to prevent electrical failures that could affect machining accuracy.

2. Strengthen the overall design of CNC lathes

Manufacturers should accelerate the optimization of CNC lathe designs, innovating CNC structures to improve stability, reliability, and precision while reducing production costs.

When optimizing CNC lathe configuration, operators should focus on detecting deformation stress, monitoring stress from accessories, and developing strategies to address deformation, improving processing precision.

To improve swing frequency monitoring efficiency in CNC processing, operators should optimize machine tool structures and implement a comprehensive inspection system. This enhances rigidity, reduces material consumption, stabilizes the center of gravity, and improves processing precision.

The lack of an ideal heat dissipation device in CNC lathes causes heat buildup from spindle components and cutting processes, leading to rapid temperature rise, thermal deformation, and reduced CNC processing accuracy.

The thermal deformation problem that occurs during the operation of the CNC lathe is characterized by instability and irregularity. Thermal deformation in a CNC lathe can cause spindle elongation and skewing, disrupting operation and severely affecting processing accuracy.

To address this issue, companies should install a heat dissipation device at the CNC lathe spindle to enhance heat dissipation, reduce spindle temperature, and minimize thermal deformation, thus improving processing accuracy.

3. Perform error compensation to achieve precision control

The semi-closed-loop servo system is the core of driving the operation of CNC lathes. The reverse deviation in CNC lathes affects positioning accuracy and part quality. Operators should use error compensation methods to mitigate their impact on processing accuracy.

Analyzing the accuracy of CNC lathes in China’s machinery manufacturing shows that adopting programming based on CNC processing standards can improve accuracy, optimize directional operations, and enhance processing precision.

To reduce the impact of reverse deviation on processing accuracy, operators should monitor the reverse clearance value, adjust coordinate displacement instructions, and transmit accurate positioning data to the CNC lathe’s control center.

4. Apply programming to improve geometric accuracy

During CNC lathe operation, interpolation corrects position deviations caused by positive errors to improve stability and reliability. Operators typically set up different storage addresses to minimize bearing gap deviations and enhance machining accuracy.

If the CNC lathe’s operating instructions change during operation, the interpolation between bearings will change. To improve data accuracy, the operator must implement programming corrections to reduce machining deviations and enhance precision.

Conclusion

With the widespread use of CNC lathe technology, processing quality and efficiency are increasing. Operators should use advanced techniques to optimize the system, ensuring CNC lathes maintain high efficiency and accuracy.