Table of Contents

Cutting is widely used in the current mechanical manufacturing field as a processing method. Improving cutting efficiency and reducing production costs are of great practical significance to promoting the national economy and national defense construction. With the development of CNC automation and high-speed cutting, auxiliary time has decreased, while cutting time has increased.

Therefore, to further improve processing efficiency, it is necessary to reduce cutting time. The main way to reduce cutting time is to increase cutting speed and cutting depth. As precision manufacturing advances, manufacturers are limited in increasing cutting depth for large-margin cuts. High-speed cutting reduces cutting time, and force, and improves surface accuracy. It has been widely used and verified by industries such as aerospace, defense, electronics, and precision machinery.

High-speed cutting technology has become a key research topic in advanced manufacturing. This paper explores its characteristics, applications, mechanisms, machine tools, tool technologies, and processes, and predicts future development trends to provide recommendations for advancing China’s high-speed cutting technology.

Overview of high-speed cutting technology

German physicist Carl J. Salomon first proposed the concept of “high-speed cutting”. His core idea is that each material has a corresponding critical cutting speed. When cutting speed is below the critical value, cutting force and temperature rise with speed; above this value, both decrease. Thus, high-speed cutting reduces processing time, cutting temperature, and tool wear, and improves surface quality.

At present, there is no unified definition of the speed of high-speed cutting. High-speed cutting is often classified in two ways: by cutting speed, defined as more than five times the conventional speed, or by spindle speed, defined as over 8000 rpm. In practice, the speed depends on the workpiece material and processing method, making it difficult to define an exact value.

It is worth noting that high-speed cutting is not just about increasing the cutting speed. It is a complex system integrating high-speed cutting mechanisms, key equipment, and processes. With the development of related technologies, high-speed cutting continues to pursue the organic unity of technological progress and benefits.

Advantages of high-speed cutting technology

1. Improve production efficiency: High-speed cutting greatly shortens processing time, is suitable for mass production, and improves overall production efficiency.

2 . Enhanced machining accuracy: The cutting force is small, the workpiece is less deformed, high-precision machining can be achieved, and the dimensional accuracy and surface quality of the parts are improved.

3. Extend tool life: The cutting temperature is lower and tool wear is reduced, significantly extending the tool life.

4 . Improve surface quality: The surface roughness of the processed workpiece is low, reducing the need for subsequent polishing and finishing.

5 . Reduce workpiece deformation: Reduced cutting force and heat minimize workpiece deformation, making it ideal for thin-walled and complex parts.

6. Wide material adaptability: suitable for various materials, including difficult-to-process materials, such as titanium alloy, stainless steel, etc.

7 . Reduce production costs: By improving cutting efficiency and extending tool life, the overall production cost can be effectively reduced.

Application of high-speed cutting technology

1. Aerospace

· Processing aircraft structural parts and engine components requires high precision and high strength.

· Especially outstanding in the processing of light alloys (such as aluminum alloys and titanium alloys).

2. Automobile manufacturing

· Manufacture key components such as engine cylinders and gearbox housings.

· Improve processing efficiency, shorten production cycles, and meet mass production needs.

3. Electronics industry

· Process the shells and internal parts of electronic products such as mobile phones and computers.

· Achieve high-precision processing to meet the needs of small-sized and complex-shaped parts.

4. Mold manufacturing

· Make precision molds such as injection molds and stamping molds.

· Improve mold processing accuracy and surface quality and extend mold service life.

5. Medical devices

· Process medical equipment and instruments, such as artificial joints, implants, etc.

· Meet high precision and high surface quality requirements.

6. Defense industry

· Manufacture parts for weapons and military vehicles.

· Improve the processing accuracy and reliability of key parts.

7. Mold manufacturing

· Manufacture plastic and metal molds, suitable for mold processing with high precision and high surface quality requirements.

·Shorten the mold manufacturing cycle and increase the mold service life.

High-speed cutting technology, known for its efficiency, precision, and low cutting force, has driven rapid growth in modermanufacturingre ng. With the continuous advancement of technology, high-speed cutting technology will show its unique advantages in more fields.

Research on key technologies of high-speed cutting

1. Research on high-speed cutting mechanism

The high-speed cutting mechanism is the core of high-speed cutting technology, guiding and controlling the entire process. Its main differences from traditional ordinary cutting mechanisms are in cutting principles, cutting heat and temperature, and chip formation. The mechanism of high-speed cutting is as follows:

·In high-speed cutting, as the tool speed increases, cutting force and temperature rise. Once the speed exceeds the material’s critical limit, both force and temperature drop, improving efficiency.

·Increasing cutting speed generates heat, causing a high-temperature area at the tool-workpiece interface, where part of the material melts, lubricating the surface, reducing friction, and cutting force.

·In high-speed cutting, serrated chips form due to material instability, causing periodic changes in cutting force and temperature, which affect process stability and results.

·Two theories explain serrated chip formation: the adiabatic shear theory attributes it to thermal softening outweighing strain hardening, while the periodic brittle fracture theory links it to periodic fracture.

The study of high-speed cutting mechanisms includes cutting principles, heat and temperature, chip formation, and more. It requires applying knowledge of heat transfer and fracture mechanics to understand the complex process. We need to conduct further research to better understand and control the formation of serrated chips in high-speed cutting.

2. Research on key equipment technology for high-speed cutting

2.1 High-speed cutting machine tools

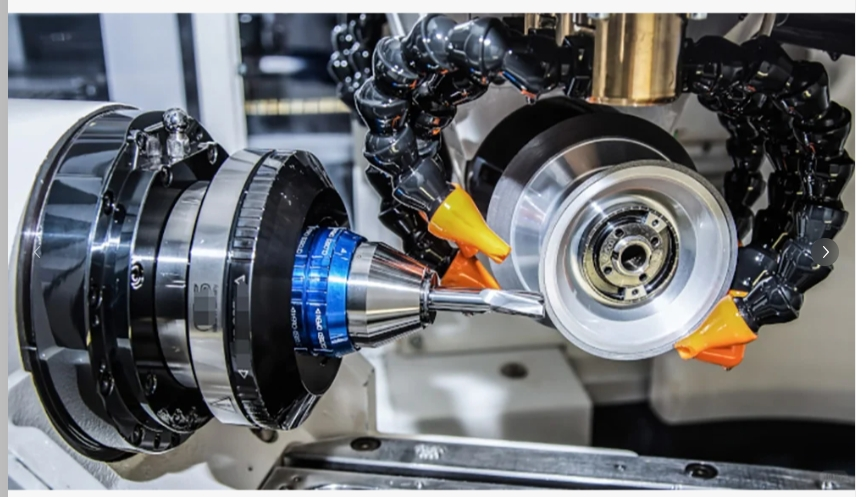

High-speed cutting machine tools are core equipment, including spindle, rapid feed, and CNC control systems.

The high-speed spindle system must have a compact structure, excellent start-stop performance, a wide speed range, high rigidity and accuracy, good thermal stability, reliable lubrication and cooling, and a stable monitoring system.

Electric spindles typically use an integrated motor and spindle, where an AC servo motor directly drives the internal structure.

Rapid feed systems must use high-speed spindles. The feed mechanism of the traditional ball screw nut pair has low transmission efficiency and cannot meet performance requirements.

To achieve high-speed precision, the guide rail features a linear structure with embedded ball bearings for low friction and a small contact area. The feed mechanism uses advanced high-speed linear motors and high-quality small-pitch ball screws. These technologies can achieve high feed speeds and accelerations and improve transmission accuracy.

In high-speed cutting, the CNC control system must enable fast data processing, predictive control, and geometric and thermal compensation.

Traditional CAD data conversion into point-to-point tool paths no longer meets requirements; contour control technologies like NURBS interpolation, smooth interpolation, and bell-shaped acceleration/deceleration can enhance performance.

2.2 High-speed cutting tools

High-speed cutting tools are crucial for modern machining, offering high precision, efficiency, reliability, and specialization material, coating,g, and structure of the tool are the keys to achieving these characteristics. The selection of tool materials and coatings is of great significance to the development of high-speed cutting technology.

Common high-speed cutting tools include TiCN-based carbide, ceramic, diamond, and PCBN tools. They each have the characteristics of being suitable for different materials.

TiCN-based carbide and ceramic tools are ideal for high-speed machining of steel and alloys, diamond tools for aluminum, titanium, and copper alloys, and PCBN tools for high-temperature alloys.

The structural parameters of the tool directly affect the tool’s life and processing quality.

Compared with traditional tools, high-speed cutting tools have smaller rake angles and larger back angles. Increasing the tip angle and cutting edge length improves tool rigidity and reduces wear.

Under high-speed rotation, the tool must be balanced, and the tool holder must clamp the tool with sufficient force and reliability.

To meet high-speed cutting requirements, manufacturers have improved tool holder positioning accuracy and connection rigidity, as seen with Japan’s BIG-PLUS and Germany’s HSK series.

The traditional solid BT tool holder has low accuracy and rigidity, failing to meet high-speed cutting needs.

They developed a close-fitting tool holder and positioned it using both the spindle’s inner hole cone and end face.

2.3 Research on high-speed cutting technology

High-speed cutting technology is very different from traditional ordinary processing technology. The design principle of high-speed cutting is to leverage its advantages for a high-efficiency, high-quality process plan.

The research on high-speed cutting technology mainly includes the selection of cutting method, cutting amount, and tool feeding method.

In high-speed cutting, machinists prefer down milling because it decreases cutting thickness, shortens the cutter sliding distance, and results in a smoother surface. Reverse milling increases cutting thickness, raising friction, radial force, and heat, which accelerates tool wear. Cutting parameters depend on the tool and material.

The selection principle for high-speed milling is generally a medium feed per tooth, small axial depth, and large radial depth.

The tool-feeding method optimization includes direction, path, and flexible acceleration/deceleration.

You should evaluate the optimization of the tool feeding direction based on the flatness of the surface. The tool path should be simple, and smooth, and use arc transitions to avoid interference areas.

To reduce start-stop impact and ensure processing accuracy, select the appropriate acceleration and deceleration method.

Prospects of high-speed cutting technology

1. Strengthen in-depth research on high-speed cutting mechanism

Although researchers both domestically and internationally have conducted extensive studies on high-speed cutting, they generally fail to meet production needs, necessitating further in-depth research.

You can strengthen in-depth research on high-speed cutting mechanisms from the following aspects:

1) Digital description and prediction of cutting force and cutting heat distribution law;

2) Research on the chip formation mechanism of difficult-to-cut materials, composite materials, and micro-cutting;

3) Description of tool-chip interface tribological behavior and tool wear mechanism;

4) Monitoring and prediction of tool life;

5) Time domain and frequency domain modeling analysis of cutting dynamics.

2. Research on new tool materials and structural technologies

Research on new tool materials and structures covers material selection, design, and processing technology.

Among them, new tool materials may include high-hardness ceramic materials, wear-resistant coating materials, high-strength metal materials, etc. The selection of these materials is closely related to the specific use of the tool.

Tool structure technology focuses on blade design, structure, and fixing methods to enhance stability, cutting efficiency, and tool life.

Research on processing technology includes optimization of cutting parameters, cooling, and lubrication technology, cutting force and heat control, etc., to achieve efficient, precise,e and stable processing.

3. Build an intelligent high-speed cutting cloud processing database

The high-speed cutting processing database can intelligently provide process data for the cutting site according to production needs. The core of the high-speed cutting database is based on the intelligent prediction of the cutting force model, cutting temperature model, tool wear model, and workpiece surface quality model.

However, with the continuous development of new processes and technologies, the cutting database has a strong timeliness.

Currently, we can use cloud computing technology and artificial intelligence theory to build an intelligent high-speed cutting cloud processing database based on the physical model of the high-speed cutting process, combined with production practices and a large number of cutting tests.

4. Research on online monitoring technology for high-speed cutting process

During high-speed cutting, the vibration and wear of the tool are crucial to the surface quality of the workpiece. To ensure the development of high-speed cutting technology, online monitoring of the tool status and workpiece surface quality has become crucial.

Online monitoring establishes a connection between the vibration and wear of the tool and the surface quality of the workpiece and sets a reasonable threshold based on a large amount of actual production experience.

This monitoring can ensure that the tool vibration signal is normal and the surface roughness of the workpiece is qualified. By adjusting the process parameters, replacing the tool, and providing feedback to adjust the equipment, we can guarantee normal high-speed cutting.

5. Research on green cutting technology based on dry-cutting

High-speed cutting can indeed reduce energy consumption to a certain extent, but it also requires a large amount of coolant, which causes certain pollution to the environment. The main development direction of the manufacturing industry in the future is green environmental protection energy conservation and emission reduction.

Among them, green cutting based on dry cutting is one of the key research areas of high-speed cutting. Dry cutting is a processing technology that does not use or only uses a trace amount of cutting fluid during the processing.

This technology can not only reduce pollution, but also save equipment related to cutting fluid, simplify the production system, and reduce production costs, which is in line with the trend of green environmental protection energy conservation, and emission reduction.

Conclusion

The research above leads to the following conclusions:

1. High-speed cutting technology is a key area of research in the current advanced manufacturing field, encompassing complex system engineering such as high-speed cutting mechanisms, key equipment technology, and processes. As related technologies develop, we continue to pursue the integration of technology and benefits.

2. Compared with conventional cutting, high-speed cutting technology has many advantages a high removal rate reduces production costs, a small cutting force reduces machining deformation, chip heat dissipation reduces thermal deformation, stable cutting and high precision, and simplified process flow improves production efficiency.

3. To promote the development of high-speed cutting technology, we need to strengthen the research on high-speed cutting mechanisms, accelerate the development of ultra-high-speed and high-power machine tools, strengthen the research on new tool materials and structural technologies, build an intelligent high-speed cutting cloud processing database, carry out research on online monitoring technology of high-speed cutting process, and focus on strengthening green cutting technology mainly based on dry cutting.